Insulation should be a priority when building your steel metal building. It’s the best way to help maintain warmth in your steel building.

Choosing the right insulation type for your metal building is an important part of reducing energy use and creating a better working environment for your steel building. When you insulate a steel building it doesn’t just impact your energy costs and controlling temperatures.

If you purchase the correct insulation for your steel building, it will prevent the growth of mold, mildew, rust, and corrosion. Educated building owners can purchase affordable, low-maintenance, and energy-efficient structures with proper insulation. We will go into detail on how to insulate your steel building properly.

How Does Steel Building Insulation Work?

Metal building insulation has many benefits that include controlling heat flow, preventing condensation, and the growth of mold/mildew, noise, and mildew. Insulation has also been known to improve the proficiency and efficiency of lighting fixtures. Insulation helps keep the air and temperature of your steel building at what you desire. During the summer keep warm air out and during the winter keep cold air out. You will see a reduction in energy usage by controlling the temperature with the assistance of your insulation. Different reflective and fiberglass insulations prevent condensation by sealing the passage of water vapor through the building. Insulation absorbs sound waves from the outside to the inside of your steel building. Different facings of insulation also help increase the efficiency of your lighting. This is done through the brightness and reflectiveness of the facings that are offered.

How To Insulate A Prefab Steel Building

You will install your insulation in traditional buildings between each stud. The difference between installing insulation in steel buildings is it typically is installed above the framing which provides more security. Insulating your metal buildings this way counters heat transfer, and moisture forming between frames, walls, and the roof.

Four Types of Insulation for Metal Building Kits

These are the four most seen insulation options for steel buildings. You must weigh each option as their benefits and costs will vary. When choosing insulation to install in your steel building it is very important to consider the building’s location, shape, and size.

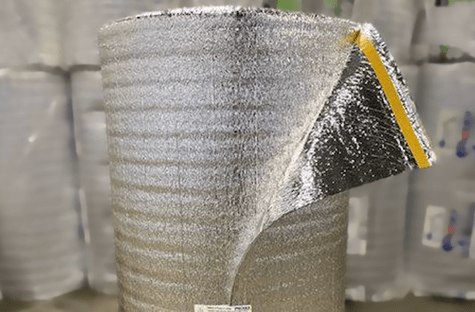

Reflective Foil Insulation

Foil bubble or also known as reflective foil insulation is known for being waterproof and having a reflective surface. That surface can significantly brighten the exterior of your building. Having this reflective surface will substantially make the exterior of your building brighter. Simple to install and can sometimes be the more expensive route when purchasing insulation. No need for protective gear when installing and you will only need nails, staples, or sometimes glue.

The Most Recommended

This insulation consists of reflective material that reflects radiant heat and is the most recommended option. It is cost-effective, energy efficient, and durable. Providing your steel building with the comfort it needs to control the temperature and eliminate condensation.

Before starting the installation make sure your steel building is completely built. You will measure each steel panel and then cut the insulation according to the measurements you took. You will use double-sided tape to keep the insulation in place. Placing this double-sided tape on the back of the insulation to stick to each panel. Then proceeding to screw the exterior steel panels to the building. Doing this with another person makes life a lot easier and should be done when the weather will not be a factor.

Advantages: The radiant barrier that this insulation provides is from aluminum strengthens the reflection of your building keeping unwanted heat out. The facing works to reinforce the insulation providing a long-term solution for the durability of your steel building. White and silver facings options are available

Fiberglass Insulation

Fiberglass is one of the most common and affordable options for insulating a steel building. You can receive fiberglass insulation typically in blankets, also known as blanket insulation. The convenience of installing this insulation is one of the main reasons this type of insulation is so common. It is important to wear protective clothing, gloves, and a mask as this insulation can irritate your skin if exposed. This insulation is more inviting to rodents, birds, and bugs since it absorbs moisture more easily.

The Easiest to Install

There are eco-friendly materials available and are one of the more durable solutions.

When installing you will want to make sure that you have the proper clothing to cover your skin as it can cause a lot of irritation if exposed. You will begin by separating strips of the fiberglass insulation at the necessary dimensions of your panels/studs. Then fill in between each panel and continue so forth. These have been known to be the easiest insulation to install and hold moisture preventing condensation.

Advantages: Easy installation, friendly for the environment, and low cost.

Disadvantages: Proper face masks, clothing, and gloves are required for installation.

Spray Foam Insulation

Foaming polymer that can be sprayed on steel walls and ceilings. Once it has been sprayed the liquid transforms into a solid material with air-filled cells that fill into spaces. Spray foam insulation is known to trap moisture when sprayed and as result will create rust and mold in your metal panels. Over time the trapped moisture can corrode and rust away the underside of the metal panels. This will eventually cause damage and lessen the value of your steel building. Spray foam is an acceptable option but not the best option when trying to maintain the integrity and structure of your building.

The Lowest Maintenance

This method can be done for commercial or residential steel buildings. It can also be used for plumbing or roofing. Like other insulations, it can be helpful to keep pests and rodents out.

This insulation can be installed in existing steel buildings. Spray foam is better to use if you are in cold or dusty environments. Spray foam can be a good solution for containing condensation and moisture.

Spray foam has some cons which include the cost and it is difficulty to remove if needed. DIY kits to do spray foam can be pricey and hiring a professional is even more expensive. Once it sets it is extremely difficult to remove and is one of the least pleasing looks for the interior of your steel building.

Advantages: Provides a texture to the inside of the building.

Disadvantages: Can void warranties for building as moisture is harder to control when installing and more expensive.

Insulated Metal Panels

This form of insulation consists of an insulated foam core sandwiched between two metal panels. This is one of the most expensive options when insulating your steel building. Insulated metal panels can provide sufficient insulation but will cost much more when budgeting for your steel building.

When purchasing a steel building it is very beneficial to install insulation to control the temperature of the building, increase its longevity, and protect your building. This is an upgrade that you will be happy you did!

It is not difficult to install and can be done in a few days if you take the proper steps in purchasing the correct insulation. It does not have to be an expensive process and provides solutions for your steel building that will last a long time. Getting the best insulation for your steel building and understanding how to install each one is important.

Radiant Barrier Insulation

| Square Ft 4′ x 175′ (700′ Sq. ft. | Wholesale Delivered Estimates R- Value 15.3 (White Facing) |

| 700 | $660 |

| 1400 | $974 |

| 2100 | $1,459 |

| 2800 | $1,598 |

| 3500 | $1,923 |

| 4200 | $2,248 |

| 4900 | $2,573 |

| 5600 | $2,897 |

| 6300 | $3,222 |

| 7000 | $3,300 |

| 7,700 | $3,498 |

| 8,400 | $3,789 |

| 9,100 | $4,080 |

| 9,800 | $4,378 |

| 10,500 | $4,602 |

| 11,200 | $4,889 |

| 11,900 | $5,175 |

| 12,600 | $5,462 |

| 13,300 | $5,749 |

| 14,000 | $5,916 |

| Square Ft 4′ x 175′ (700′ sq. ft.) | Wholesale Delivered Estimates R-Value 17 Silver appearance |

| 700 | $660 |

| 1,400 | $974 |

| 2,100 | $1,459 |

| 2,800 | $1,598 |

| 3,500 | $1,923 |

| 4,200 | $2,248 |

| 4,900 | $2,573 |

| 5,600 | $2,897 |

| 6,300 | $3,222 |

| 7,000 | $3,300 |

| 7,700 | $3,498 |

| 8,400 | $3,789 |

| 9,100 | $4,080 |

| 9,800 | $4,378 |

| 10,500 | $4,602 |

| 11,200 | $4,889 |

| 11,900 | $5,175 |

| 12,600 | $5,462 |

| 13,300 | $5,749 |

| 14,000 | $5,916 |

| Square Ft 4′ x 85.3 (341′ sq. ft.) | Wholesale Delivered Estimates High R-Value 22 #1 BEST SELLER!! |

| 1,705 | $1,648 |

| 2,387 | $2,188 |

| 3,069 | $2,737 |

| 3751 | $2,993 |

| 4,433 | $3,355 |

| 5,115 | $3,777 |

| 5,797 | $4,350 |

| 6,479 | $4,609 |

| 7,161 | $4,937 |

| 7,843 | $5,379 |

| 8,525 | $5,820 |

| 9,207 | $6,362 |

| 9,889 | $6,783 |

| 10,571 | $7,090 |

| 11,253 | $7,422 |

| 11,935 | $7,754 |

| 12,617 | $8,285 |

| 13,299 | $8,617 |

| 13,981 | $9,049 |

| 14,663 | $9,480 |

Fiberglass Insulation

| Sq. Ft. | Wholesale ESTIMATES R-Value 10 (3”) |

| 600 | N/A |

| 1,200 | $1,311 |

| 1,800 | $1,645 |

| 2,400 | $1,972 |

| 3,000 | $2,295 |

| 3,600 | $2,662 |

| 4,200 | $2,982 |

| 4,800 | $3,333 |

| 5,400 | $3,630 |

| 6,000 | $3,873 |

| 6,600 | $4,352 |

| 7,200 | $4,676 |

| 7,800 | $4,961 |

| 8,400 | $5,324 |

| 9,000 | $5,684 |

| 9,600 | $6,019 |

| 10,200 | $6,358 |

| 10,800 | $6,700 |

| 11,400 | $7,260 |

| 12,000 | $7,381 |

Roll Width

3′, 4′, 5′, and 6′

Ready buyers, fill out a QUOTE -ORDER FORM.

| Sq. Ft. | Wholesale ESTIMATES R-Value 13 (4”) |

| 600 | N/A |

| 1,200 | $1,533 |

| 1,800 | $1,975 |

| 2,400 | $2,413 |

| 3,000 | $2,900 |

| 3,600 | $3,333 |

| 4,200 | $3,748 |

| 4,800 | $4,235 |

| 5,400 | $4,677 |

| 6,000 | $5,082 |

| 6,600 | $5,566 |

| 7,200 | $5,965 |

| 7,800 | $6,413 |

| 8,400 | $6,897 |

| 9,000 | $7,344 |

| 9,600 | $7,738 |

| 10,200 | $8,228 |

| 10,800 | $8,709 |

| 11,400 | $9,020 |

| 12,000 | $9,559 |

Thickness

3″, 4″, 5″, 6″ and 8″

Ready buyers, fill out a QUOTE-ORDER FORM

| Sq. Ft. | Wholesale ESTIMATES R- Value 19 (6”) |

| 600 | N/A |

| 1,200 | $1,706 |

| 1,800 | $2,250 |

| 2,400 | $2,897 |

| 3,000 | $3,359 |

| 3,600 | $3,811 |

| 4,200 | $4,404 |

| 4,800 | $4,968 |

| 5,400 | $5,566 |

| 6,000 | $6,031 |

| 6,600 | $6,531 |

| 7,200 | $7,328 |

| 7,800 | $7,741 |

| 8,400 | $8,173 |

| 9,000 | $8,765 |

| 9,600 | $9,154 |

| 10,200 | $9,720 |

| 10,800 | $10,242 |

| 11,400 | $10,906 |

| 12,000 | $11,319 |

R- Values

8 to 30

Ready buyers, fill out a QUOTE-ORDER FORM

Average savings is 10% below market quotes of equal specification standard. Guaranteed savings is a net of $1,000 on steel buildings and $200 on insulation below market quotes.

1. Review Building or Insulation delivered estimates.

2. Ready buyers, fill out a Quote – Order Form

3. Must pay profit-fee amount AFTER (same day) quoted savings!

Wholesale Building Costs + Profit

$0 to $100,000 | Profit $1,000

Wholesale Insulation Cost + Profit

$0 to $25,000 | Profit $500

Cost-Plus Program Made Simple

A 35-year industry veteran presents a spiritual approach by allowing those prepared to give back TODAY a wholesale quote without an upfront cost.

- Review 1 to 3 market quotes as well as our posted insulation prices and steel building prices.

- Fill out one of these forms: Name Your Price, Wholesale Metal Building Quote, and Wholesale Insulation Quote.

- Call 1-888-512-1116 to let a representative know you submitted a form and to go over the details submitted.

- After the quoted savings, pay the low service fee that SAME DAY: $350-$500 Insulation orders – $750-$1,500 Steel Building orders.

- For a full process, click – Order To Delivery

- Reflective insulation is delivered in 7-10 days. Receive Order #. Ships the next day! Receive a call from the shipper before delivery.

- Fiberglass insulation is delivered in 2-3 weeks. Receive Order #. Receive a call from the shipper before delivery.

- Steel Building Kits are delivered in 8-10 weeks. Receive the Order # and Scheduling information. Certified plans completed within 4 weeks. Receive a call from the shipper before delivery.