Cheap Pole Barn Insulation Prices

Factory Steel Overstock offers the highest quality certified insulation for pole barns. There are 9 popular insulation types below. FSO provides a wide range of R-values from 8 to 30 and numerous facing options, allowing you to choose the best insulation for your needs. The public can review the wholesale prices at their convenience and choose to whether to buy fiberglass insulation online ($350 profit amount) or request a wholesale quote ( $350 to $500 profit amount). There are no upfront cost. Everyone sees the delivered price before paying the fee. With Factory Steel Overstock, you no longer have to let a commission salesman arbitrarily determine your pole barn insulation price! You see posted daily cheap pole barn insulation prices!

Reflective (White) Cheap Pole Barn Insulation Prices Insulation (4′ x 175′)

Reflective (Black Faced)Cheap Pole Barn Insulation Prices (4’x 175′)

Foil Fiberglass Vinyl Insulation for pole barns – 4′ x 125′

Cheap Pole Barn Insulation Prices Foil Fiberglass Vinyl Insulation 6′ x 125′

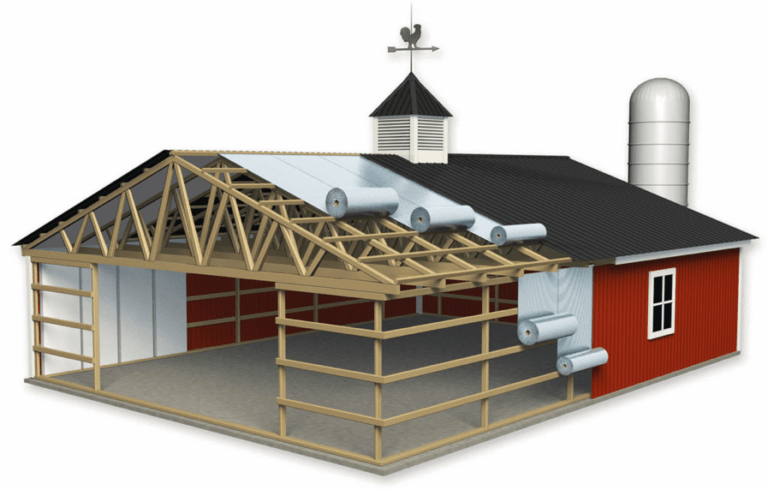

Insulation For Pole Barns

Should I insulate my pole barn?

Your pole barn is an investment, and it should be protected. Insulating your pole barn increases its comfort, functionality, and longevity, making it a wise investment.

When installing pole barn insulation, you stabilize the interior temperature, making it more energy-efficient, which reduces heating and cooling costs. In addition, it protects the structure against moisture and condensation, which can cause mold and mildew. Ultimately, this will eventually cause damage to stored items, structural decay, and possible illness.

Pole Barn Insulation Options

Several cheap pole barn insulation prices are available on this page (above). Spray Foam and Rigid foam boards are also popular types, but we don’t post their pricing because of their higher cost.

The fiberglass batt is the most popular pole barn insulation because it is cost-effective and easy to install. Spray foam provides excellent air sealing and high R-values but is more expensive. Though the Rigid foam boards offer moisture resistance and thermal efficiency, they also come at a higher cost. Traditionally, Reflective insulation is ideal for temperature control in warmer climates. Factory Steel Overstock’s high R-Value Reflective Insulation suits colder climates; however, fiberglass may be the preferred choice in cold areas. Ultimately, choosing the right type of insulation will depend on the barn’s environment, budget, and specific needs. Please review our Cheap Pole Barn Insulation Prices above.

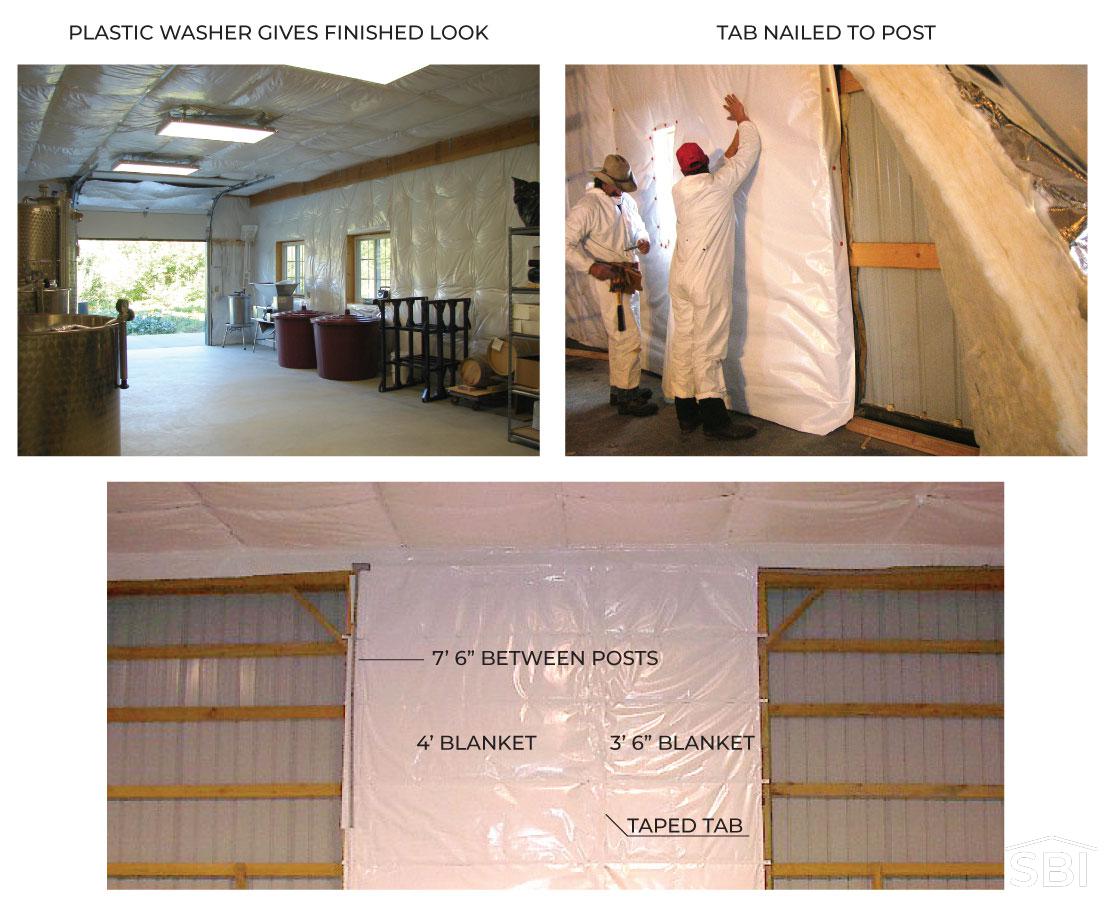

How to Install Reflective Insulation in a Pole Barn

This is a brief and general instruction process for installing reflective pole barn insulation: The first thing to do is measure the spaces between the frames and cut the insulation material you have chosen to fit between these areas. When you use reflective insulation, the glossy, reflective side faces the open-air space.

The pole barn insulation should be secured to the framing using staples, adhesive tape, or bands. Overlap the seams between pieces to ensure there are no gaps. The last thing you will do is use tape to close off the edges and joints. Make sure you review the several Cheap Pole Barn Insulation Prices posted

How to Install Fiberglass Insulation in a Pole Barn

To install fiberglass insulation, start by measuring the spacing between the framing members because you will need to cut the fiberglass to fit these spaces. While handling fiberglass, it would be wise to wear protective gear like gloves and a mask. You can start at one end and place the batts between the framing, ensuring the Vinyl vapor barrier side faces the barn’s interior. This will prevent moisture issues.

For maximum effectiveness, ensure the batts fit securely by using staples along the edge of the framing. You don’t want gaps. Finally, the insulation should be covered with a finishing material like plywood or drywall to protect and conceal it.

Pole Barn Fiberglass Blanket Insulation Rolls

All insulation roll types are designed to enhance thermal efficiency and control structure condensation. Fiberglass insulation rolls are one of the better types. These rolls are made from fine glass fibers that trap air, slowing heat transfer and providing adequate insulation. The thicker the roll, the more effective it will be.

Fiberglass insulation rolls are easy to install. They roll out and are cut to fit between the barn’s framing members. Most orders include a VRR+ vapor barrier on one side, which should face the interior to prevent moisture accumulation.

What Pole Barn Insulation R-Value Should I Have?

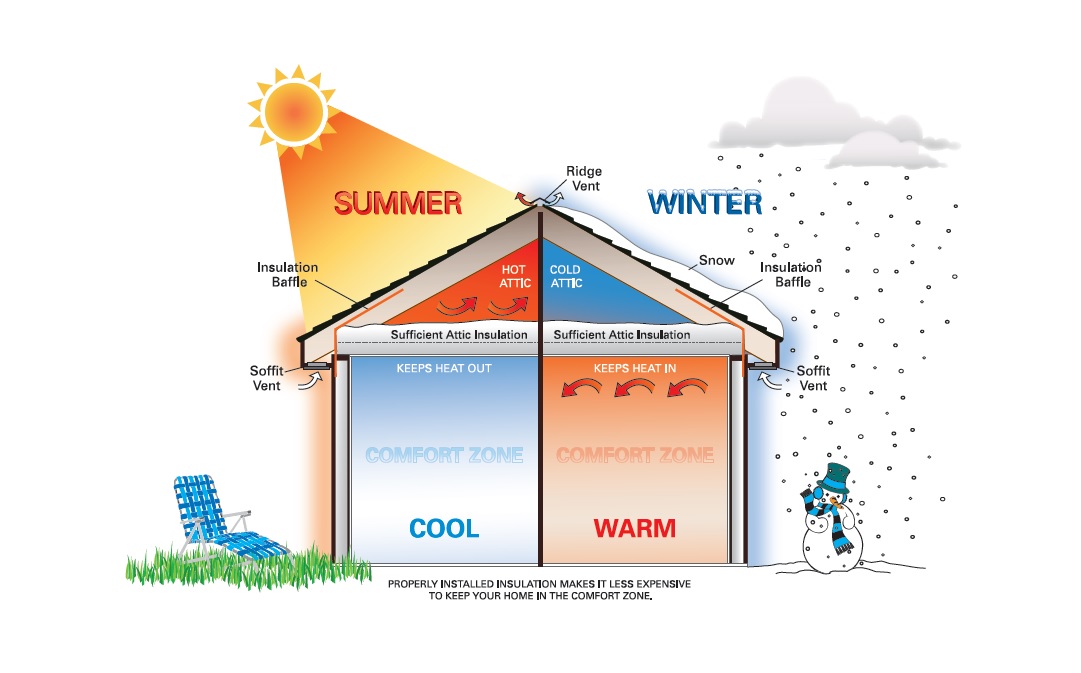

Choosing the correct R-value for pole barn insulation is essential for optimal energy efficiency. The key factors are your geographic location, climate, and the building’s purpose.

The R-value measures the insulation’s resistance to heat flow; higher values mean better insulation. In cold temperatures, especially if one intends to be in the structure often or for long periods, a higher R-value (R-30 to R-49) is usually selected for retaining heat. A lower R-value (R-19 to R-30) may suffice in milder zones. Again, one of the R-value factors is the purpose of the building. For instance, if the building is mainly for storage, the R-value is usually selected from R-10 to R-19.

Consulting local building codes can also provide guidelines on recommended R-values. In conclusion, consider your needs, such as energy cost savings, comfort, and activities conducted inside the barn.

Pole Barn Insulation Sale Prices

With Factory Steel Overstock’s cost-plus program, it’s like having pole barn insulation for sale daily. There are no upfront costs to see low pole barn insulation prices. Start by reviewing posted prices, then decide whether to buy online or have a custom quote completed. The public pays only $350 above cost for fiberglass insulation online orders and $350-$500 for custom quoted orders. All quotes are guaranteed below-market quotes of equal specifications.

After receiving a confirmed price savings, pay the low fee that same day.

- Reflective Insulation: Insulation for pole barns are delivered in 7-10 days.

- https://www.insulation4less.com/affiliate/factorysteeloverstock

- Fiberglass insulation: Insulation for pole barns are delivered in 14-21 days. For 7-10 day delivery, a $100 fee is added.

Helpful Videos

Click to read more Testimonials

9 Reasons to Have Reflective Insulation for Pole Barns

1. Easy Installation

- Apply our double-sided tape on the top of the purlins. Initially, applying the tape will help secure insulation and prevent it from blowing into the wind.

- Roll insulation perpendicular to and over the purlins. It would be wise to let the insulation sag 1 to 3 inches. Then, seal at the seam accordingly.

- Attach your sheeting.

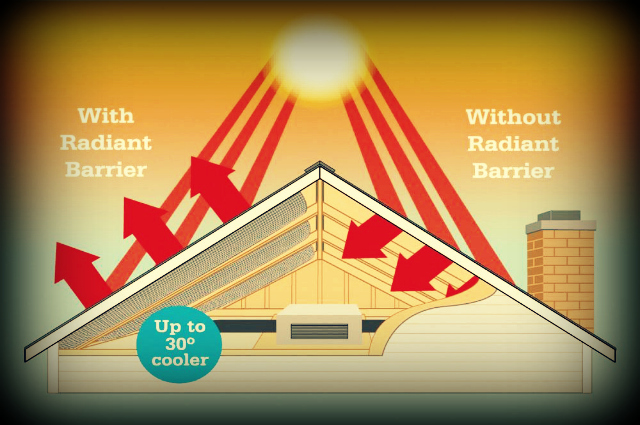

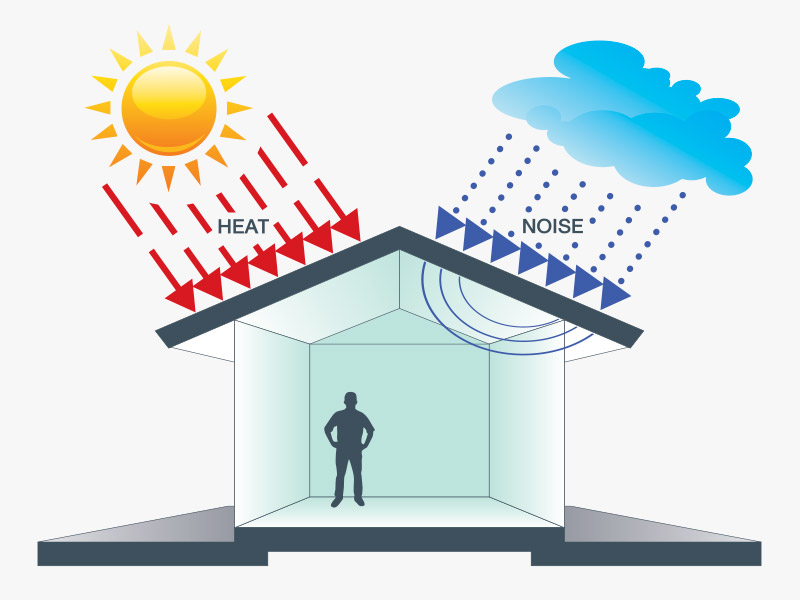

2. Stops Heat Transfer

An insulation R-value measures a material’s ability to stop heat and cold transfer. Insulating a metal building is valuable regardless of its usage. Because of their unique nature, steel buildings require a vapor and radiant barrier.

- The summer heat (the sun’s rays) on a steel surface will create extreme heat inside the building.

- In addition, the cold winter temperatures are exaggerated by the metal roof and wall sheeting, making it frigid inside. Warm temperatures in contact with cool metal roofs or walls create sweating (condensation).

The best part, you can review Cheap Pole Barn Insulation Prices Online

3. Stops Mold and Mildew

We’ve all seen some form of discoloration on walls. This is a reflection of a type of mold or mildew. These are the primary types of fungi that can grow in your building if you don’t have the proper insulation:

- Aspergillus niger

- Aspergillus avus

- Aspergillus versicolor

- Penicillium funiculosum

- Chaetomium globosum

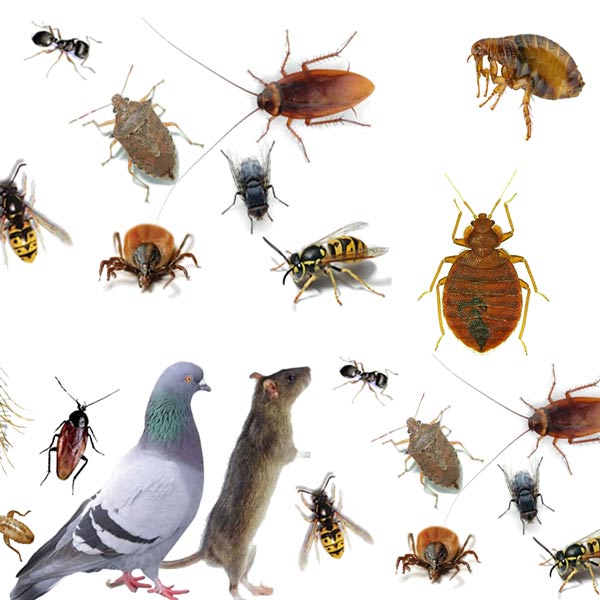

4. No Rodents, Bugs, or Birds can Nest

Protecting your building from rodents, bugs, and birds is essential. These creatures will naturally create nests in fiberglass insulation. However, they cannot do it with Factory Steel Overstock’s High R-Value reflective foil insulation.

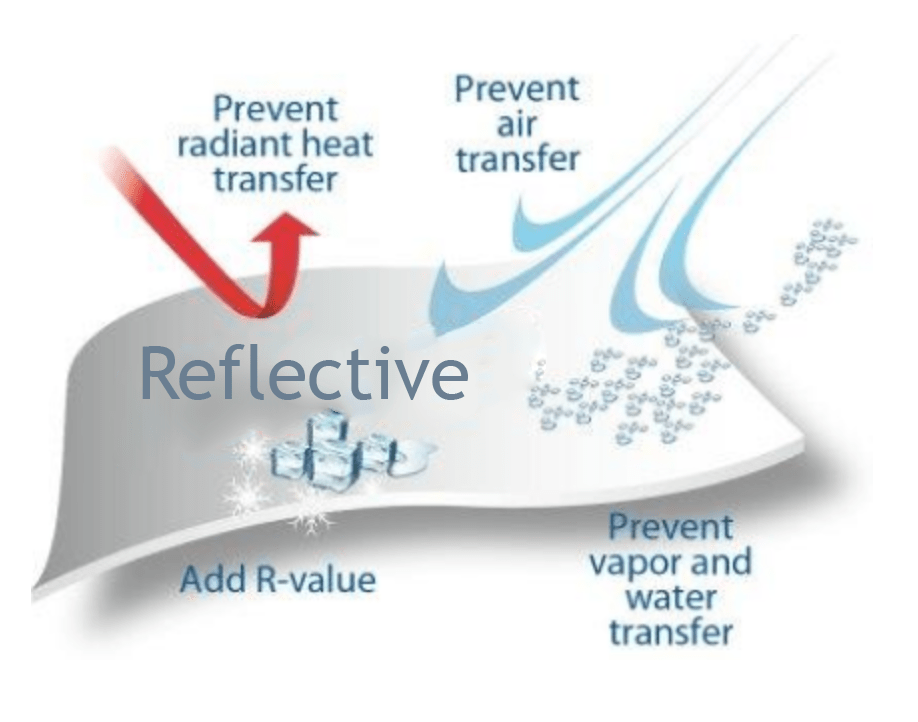

5. Stop Condensation

Most are unaware that condensation is the #1 cause of damage within pole barns. Condensation occurs when warm air contacts a cold surface. Factory Steel Overstock’s insulation prevents moisture from occurring on the roof sheeting. Simply put, it keeps the building temperature the same as outside, so there is no condensation.

6. Reduces Air Flow

Air carries moisture that can impact the temperature and integrity of a building. The airflow within a pole barn determines the spread of toxic smoke and gasses. Air barriers separate garages and conditioned spaces. The air barrier also acts as a gas barrier.

7. Prevents Leaking

Factory Steel Overstock’s High R-Value reflective pole barn insulation doesn’t leave gaps around nails or screws, it seals.

8. Vapor Barrier

Our reflective pole barn insulation is the best vapor barrier in the industry because of its closed-cell polyethylene foam and reflective reinforced foil facing. Another advantage is our reflective insulation has no leaks because it seals around nails and screws.

9. Reduces Sound of Rain and Hail

The sound of rain or hail can deafen. Factory Steel Overstock’s High R-Value insulation is the perfect source to reduce this noise dramatically.

6 Reasons to Use Fiberglass Insulation for Pole Barns

1. Thermal Efficiency

Fiberglass insulation has high thermal resistance or R-value options, effectively reducing heat transfer. This keeps your pole barn warmer in winter and cooler in summer, improving comfort and reducing energy costs.

2. Cost-Effective

Fiberglass insulation is more affordable than other insulation materials like spray foam. It provides a cost-effective solution for maintaining temperature without a significant initial investment.

3. Ease of Installation

Fiberglass insulation is relatively easy to install, especially in pole barns’ post-frame construction. It can be cut to fit between posts and secured with minimal specialized tools or skills.

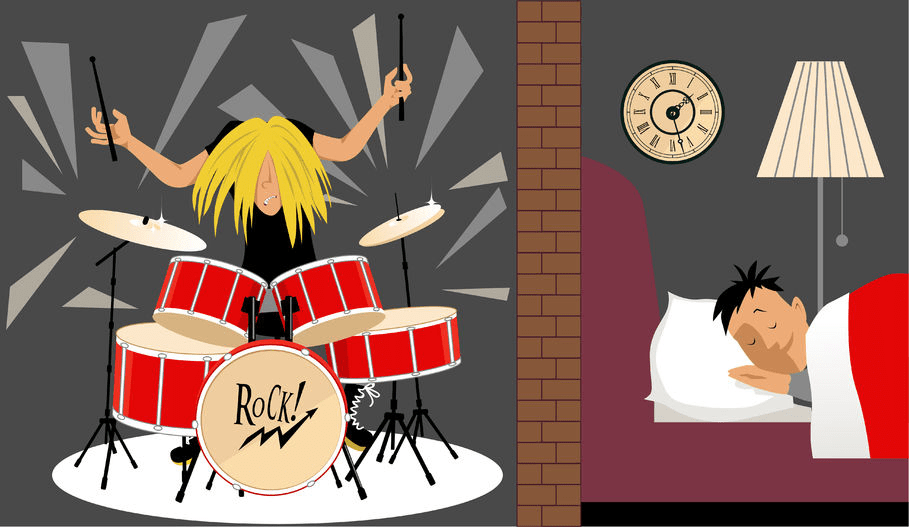

4. Sound Dampening

Fiberglass has excellent acoustic properties, including sound absorption and thermal insulation. These properties reduce noise transmission from external sources, making the pole barn quieter.

5. Moisture Resistance

Fiberglass pole bar insulation is often faced with a vapor retarder, which helps prevent moisture penetration. This is crucial in a pole barn to avoid damp conditions leading to mold growth and structural damage.

6. NIA, NAIMA, and ASTM Certified

These fiberglass certifications are the gold standards for insulation. Factory Steel Overstock only aligns with fiberglass products that meet or exceed these standards.