Calculate a delivered price for High R-Value 22 Reflective Insulation in seconds below.

No longer pay the high prices for comparable R-Values Spray foam or foam board insulation types. Our high R-value 22 reflective insulation Does It All: it is a Radiant Barrier, a Vapor Barrier, and an Air Barrier! That means it is a solution for heat, cold, and condensation! It is our #1 Reflective Insulation seller, that can be delivered in 7 days. Roll Size 4′ X 85.3′ (341′ sq. ft)

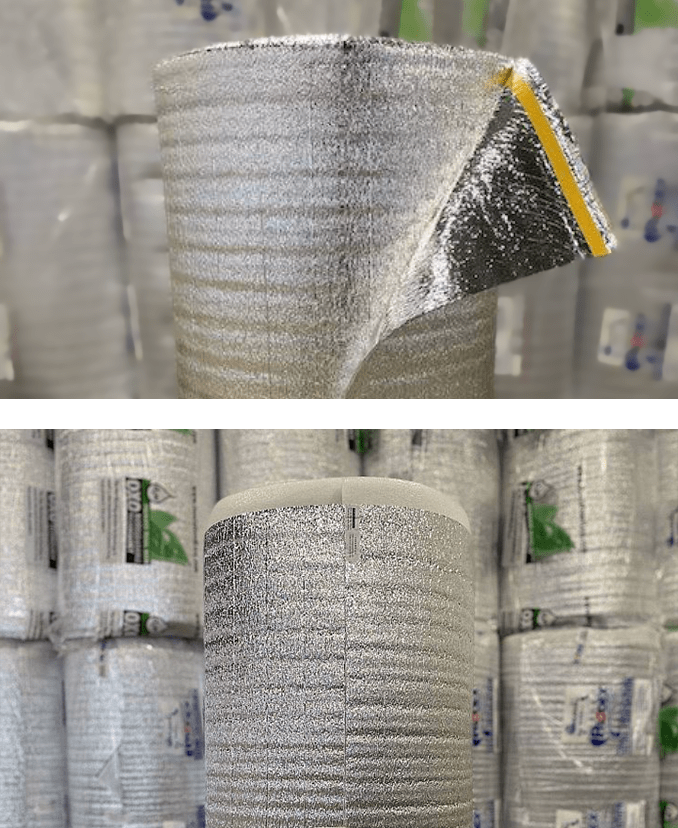

High R-Value 22 Reflective Insulation

- 97% Radiant Barrier Protection

- Strong Longitude Strength

- Easy Install

- Doesn’t easily Tear

- 10 mm thickness (0.4”)

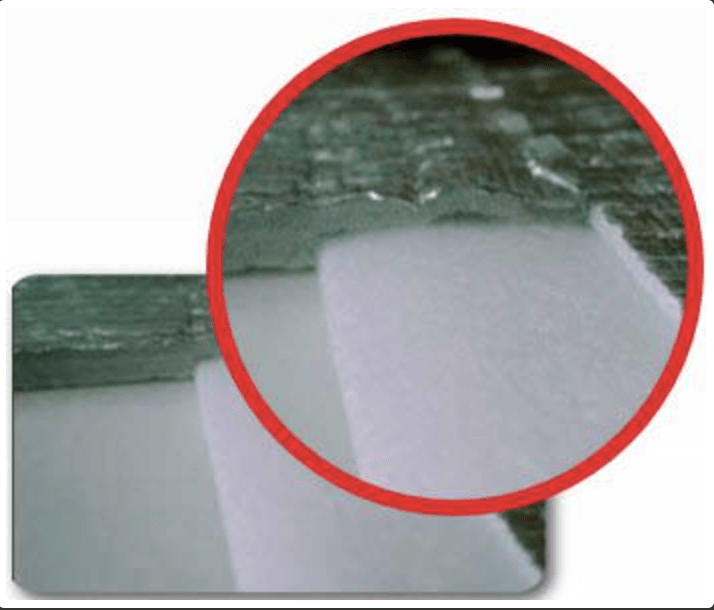

You don’t need tape to seal the r-value 22 reflective insulation rolls together. The rolls have slits on the edge so that they can overlap. Use a hot air gun and hand pressure to seal the rolls together firmly. This thermal welding process creates an impermeable overlapping seal. It will keep your structure cool in the summer and warm in the winter. Excellent 97% Radiant Barrier Protection. Questions call 1-888-512-1116

The PRODEX R-Value 22 Reflective Insulation estimated roll delivered cost is $279.95. Estimate a price below, then fill out a wholesale quote form or request a discount link to buy online on our supplier’s site.

Roll Size 4′ X 85.3′ (341′ sq. ft)

97% Radiant Barrier Protection

Buy Reflective Radiant Barrier R-Value 22 Insulation

After reviewing posted estimates, fill out a Wholesale Insulation Quote. There are no gimmicks or hidden costs. You are promised a savings below market quotes!

- Fill out a Wholesale Insulation Quote or request a DISCOUNT link to buy PRODEX Radiant Barrier R-Value 22 Insulation online on our supplier’s site.

- If you elect to receive a wholesale quote, call 1-888-512-1116 to let our representative know you completed a quote form.

- After receiving the quoted savings, pay the low brokerage fee that corresponds to the delivered cost that same day (cost-plus fee chart below).

- Ideally, for radiant barrier R-Value 22 insulation orders, pay Factory Steel Overstock the insulation cost + the service fee at the time of the initial order. If a credit card is used, there is an additional 3%. Factory Steel Overstock will take care of the order from submission to delivery and beyond, ensuring a seamless experience with its A+ Better Business Bureau and 5-star rated service. After submitting an order, there is nothing for you to do except sign for delivery.

- Radiant Barrier R-Value 22 insulation is delivered in 14-21 days. Expedited delivery is 7-10 for an additional $100. Receive Order #. Ships the next day! Receive a call from the shipper before delivery.

| Reflective Insulation Wholesale Cost | To Buy Radiant Barrier R-Value 22 Insulation Online – Call 1-888-512-1116 for Affiliate Link | Quoted Order Low Brokerage Fee |

| $0 – $1,000 | N/A | $175 |

| $1,001 – $3,000 | N/A | $300 |

| $3,001 – $5,000 | N/A | $400 |

| $5,001 – $7,000 | N/A | $500 |

| $7,001- $10,000 | N/A | $650 |

| $10,001- $15,000 | N/A | $750 |

| $15,001 – $20,000 | N/A | $1,000 |

Features: High Value Reflective Insulation

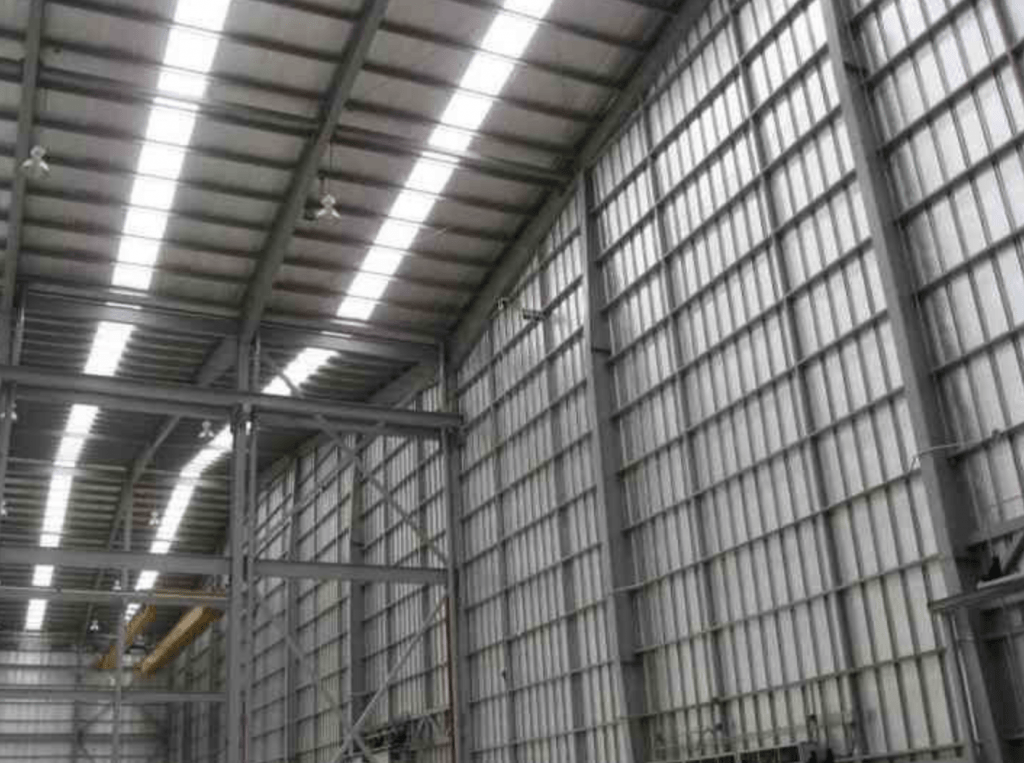

Specially designed for large metal structures, pole barns, and roofing, its exceptional longitudinal durability and enhanced tear resistance enable it to cover extensive areas effectively. Additionally, it plays a crucial role in a comprehensive home insulation setup. Integrating insulation advantages with vapor, radiant, and air barrier protection, it ensures your building remains cool and moisture-free during summer, and warm and dry throughout the winter. Regarded as the optimal insulation choice for metal constructions and pole barns.

Specifications: R-Value 22 Reflective Insulation

- It is ICC-ES Recognized

- R-Value unaffected by outside humidity

- 97% Radiant Barrier Protection (the primary source of heat flow)

- Is a vapor barrier

- Prevents condensation

- 19 dba contact noise reduction

- 90 Celsius (194 F) contact temperature rating

- UV resistance

- Center is polyethylene foam instead of air bubbles.

- Material does not allow mold or mildew

- Does not provide for nesting or rodents, bugs or birds

- Easy seals around nails (no leaks)

- 100% recyclable virgin raw materials; therefore eco -friendly.

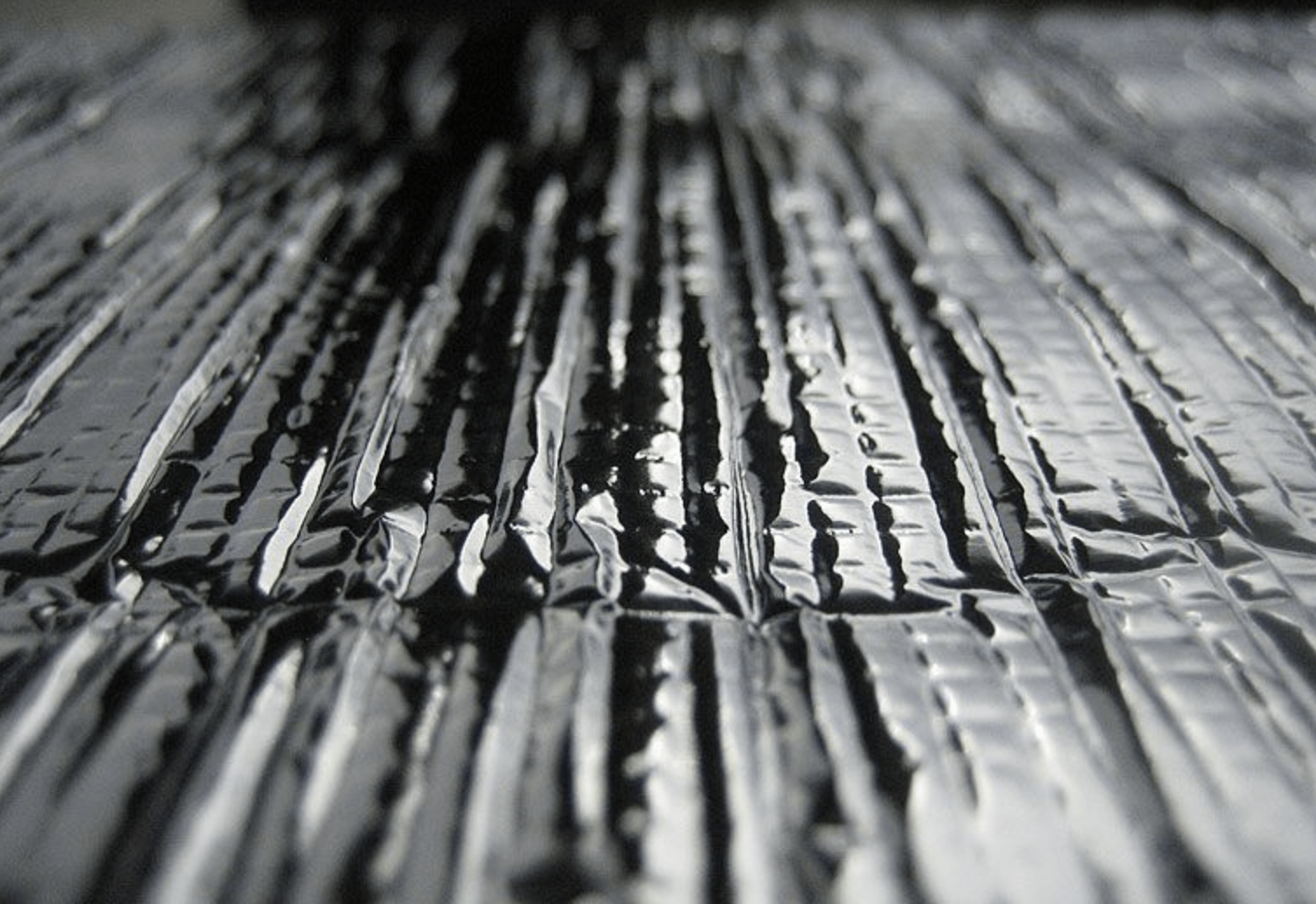

- Its surface keeps it airflow

- Lighter weight; therefore, less cumbersome installation than fiberglass batt

- Significant price savings over fiberglass batt and spay of same R-Value standard

- Delivery times (fiberglass average delivery is 2 to 3 weeks vs. reflective is 7 to 10 days).

Resistance to Growth of Fungi

- Aspergillus niger

- Aspergillus avus

- Aspergillus versicolor

- Penicillium funiculosum

- Chaetomium globosum

- ASTM C 1338

Specifications: R-Value 22 Reflective Insulation

- 97% Radiant Barrier Protection

- 4′ X 85.3′ (341′ per roll)

- 10 mm thickness

- Increased R- Value

- Added longitudinal strength

- Improved tear resistance

- Flame Spread – ZERO

- Use a hot gun to melt the polyethlene foam at the edges overlapping rolls. Add mild pressure. This will create “very” tight connection!

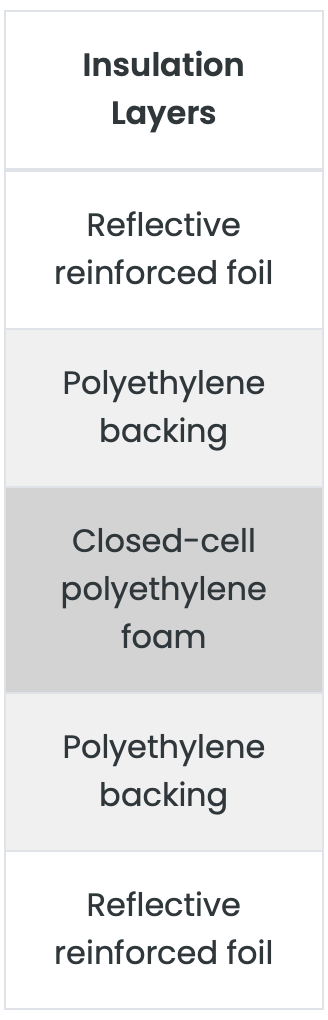

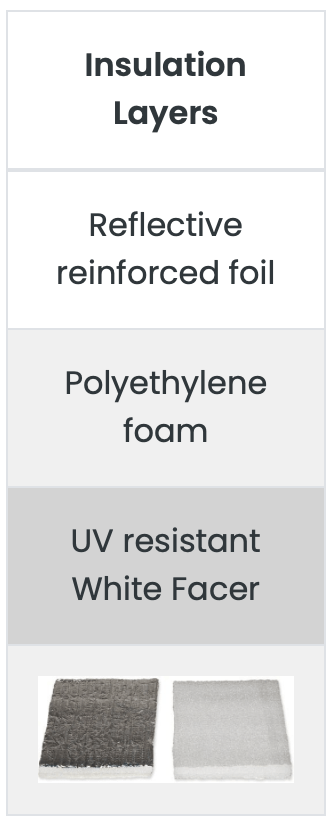

R-Value 22 Reflective Insulation Layers

- Reflective reinforce foil

- Polyethylene backing

- Close -cell polyethylene foam center

- Reflective reinforce foil

| Characteristics | Value | Regulation |

| Nominal Thickness | 0.40″ (10mm) | |

| Flame Spread Index | 0 | ASTM E 84-10 |

| Smoke Developed Index | 5 | ASTM E 84-10 |

| Fungi Resistance | No Growth | ASTM C 84-10 |

| Tensile Strength at Break (MD) | 17.27 Lbf/inch | ASTM E 96-05 |

| Water Vapor Permeance | 0.011 Perms | ASTM E 96-05 |

Resistance to Temperature and Humidity: Exhibits no signs of corrosion, delamination, or deterioration in metalization as per ASTM C-1258-08 standards.

Factory Steel Overstock’s High R-Value Reflective Insulation is the best insulation for Pole Barns and Steel Buildings

Why buy High R-Value 22 Reflective Insulation: This thicker 10 mm insulation offers the public a high R-value protection, yet costs less than other insulation with comparable R-values. It is used for various building types and climates; however, most use it in hot or human areas. It is used in attics, walls, roofs, and floors, in both new construction and retrofit projects. Like other reflective insulations, it is lightweight and easy to install. Use a hot gun to melt the polyethylene foam at the edges of overlapping rolls. Add mild pressure.

This high R-value 22 Reflective Insulation is our # 1 reflective seller. This is the perfect insulation if you want exceptional radiant heat and condensation protection. This insulation is durable, and you can quickly seal the seams with a heat gun instead of using tape.

R17 & 22 Values

R-Value 15.3

| Square Ft 4′ x 85.3 (341′ sq. ft.) | Wholesale Delivered Estimates High R-Value 22 Reflective Insulation #1 BEST SELLER!! Shipping location and # of rolls purchase influences final price |

| 1,705 | $1,648 |

| 2,387 | $2,188 |

| 3,069 | $2,737 |

| 3751 | $2,993 |

| 4,433 | $3,355 |

| 5,115 | $3,777 |

| 5,797 | $4,350 |

| 6,479 | $4,609 |

| 7,161 | $4,937 |

| 7,843 | $5,379 |

| 8,525 | $5,820 |

| 9,207 | $6,362 |

| 9,889 | $6,783 |

| 10,571 | $7,090 |

| 11,253 | $7,422 |

| 11,935 | $7,754 |

| 12,617 | $8,285 |

| 13,299 | $8,617 |

| 13,981 | $9,049 |

| 14,663 | $9,480 |

Related Products

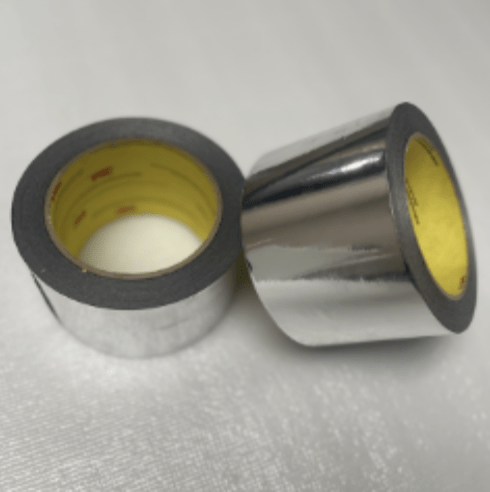

Reflective Tape

$168.95

Reflective tape plays a crucial role! Sealing seams with this tape enhances the efficiency of insulation. Available in packs containing 8 rolls, each set measures 2.83 inches by 480.8 yards in total, covering an area of 4500 square feet of insulation.

Pins and Caps

$358.95

$1000 sets of 1-5/8″ pins accompanied by 1- 1/2″ circular lock washers, amounting to 2000 pieces in total. Suggested placement involving one hanger per every 2 square feet. These 14L perforated base insulation hangers are specifically crated for installations of our reflective installation.

Double Sided Tape

$78.95

Double-sided adhesive tape, available in a package of 4 rolls, each being 1-1/2 inches wide and 60 yards long, is designed for securing insulation material to surfaces. This set is capable of effectively serving up to 2000 square feet of insulation area.

Super Metal Sealant

$94.95

Super Metal Adhesive: Sold in a pack of 12 tubes, this sealant efficiently bonds insulation materials to a wide range of surfaces.