Reflective Insulation Resources Guide

This is a reflective Insulation resource guide on types of insulation, Installation Steps, and the benefits of using reflective insulation.

Reflective Insulation Types

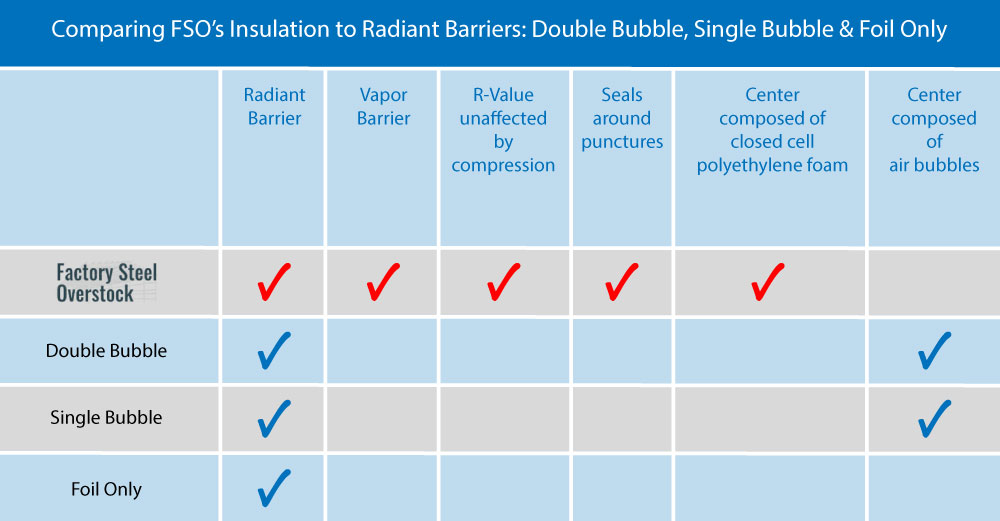

- Reflective Foil Only

- Single Bubble

- Double Bubble

- High R-Value Radiant Layered Insulation

We consider Foil-Faced Fiberglass and Foil Fiberglass Vinyl a part of the Fiberglass Insulation field. These particular insulation types are listed in the Metal Building Insulation section.

Pictures of the Four Reflective Insulation Types

- Foil Reflective Insulation. Single foil reflective insulation, although it effectively reduces radiant heat transfer, provides limited insulation against conductive and convective heat transfer. Over time, its performance may decline due to the accumulation of dust. Moreover, it may not offer adequate insulation in colder regions

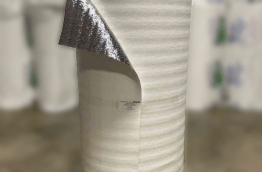

- Bubble Reflective Insulation

- Reflective Bubble Insulation is composed of air bubbles sandwiched between metal surfaces. This insulation type does offer an R-value and a radiant and vapor barrier. Though Factory Steel Overstock offers Reflective Bubble Insulation, most customers prefer the High R-value Radiant Layered Insulation offered by Factory Steel Overstock. Its polyethylene foam insulation center keeps its shape when exposed to numerous forces. This is very important! Under pressure, if insulation collapses, it loses its capacity to be an effective radiant and vapor barrier. With a 6-psi pressure, the High R-Value insulation only collapses 6%. Plus, when the pressure is relieved, it fully forms back to its initial shape! This is not the case with Single or double-bubble insulation.

- Double Bubble Reflective Insulation

- A double bubble means a second layer of bubbles; however, we have found that there isn’t much difference in performance between single and double. Once a bubble is punctured, it loses some of its shape and radiant and vapor protection.

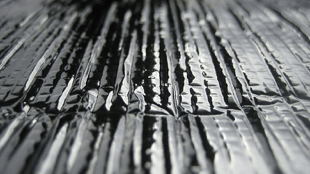

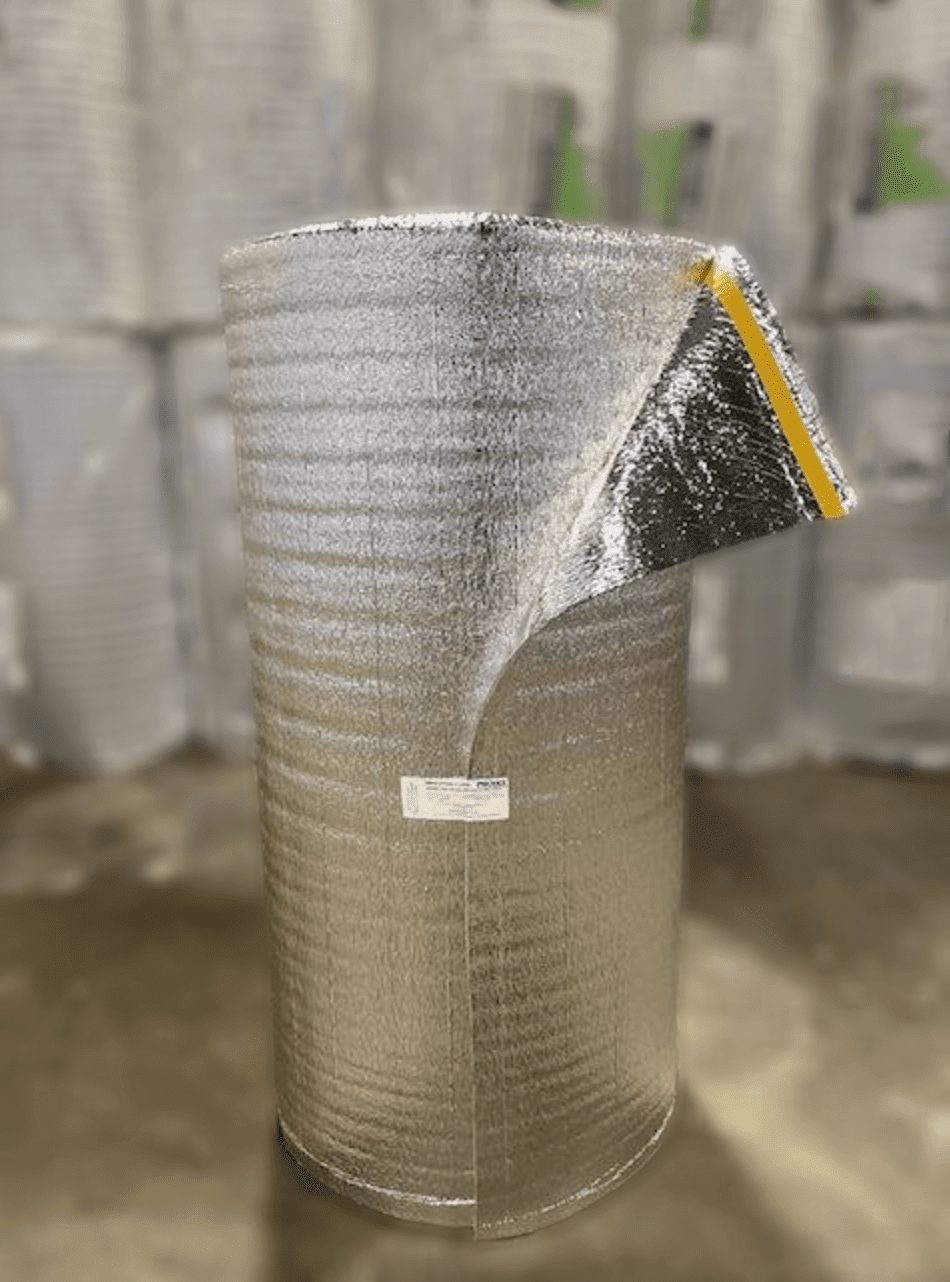

- High R-Value Radiant Layered Reflective Insulation

Finally, a Radiant Layered, High R-Value Reflective Insulation is an ALL-IN-ONE solution for HEAT, COLD, CONDENSATION, AND MORE!

The creases in Factory Steel Overstock’s high-R-Value Reflective Radiant Layered Insulation foil allow additional airflow. This is just one reason it is the industry’s highest-reflective R-value insulation!

8 Reasons Why to Buy Reflective Insulation

2. Reflective Insulation Stops Mold and Mildew

We’ve all seen some form of discoloration on walls. This is a reflection of a type of mold or mildew. These are the primarily types of fungi that can grow in your building if you don’t have the proper reflective insulation:

- Aspergillus niger

- Aspergillus avus

- Aspergillus versicolor

- Penicillium funiculosum

- Chaetomium globosum

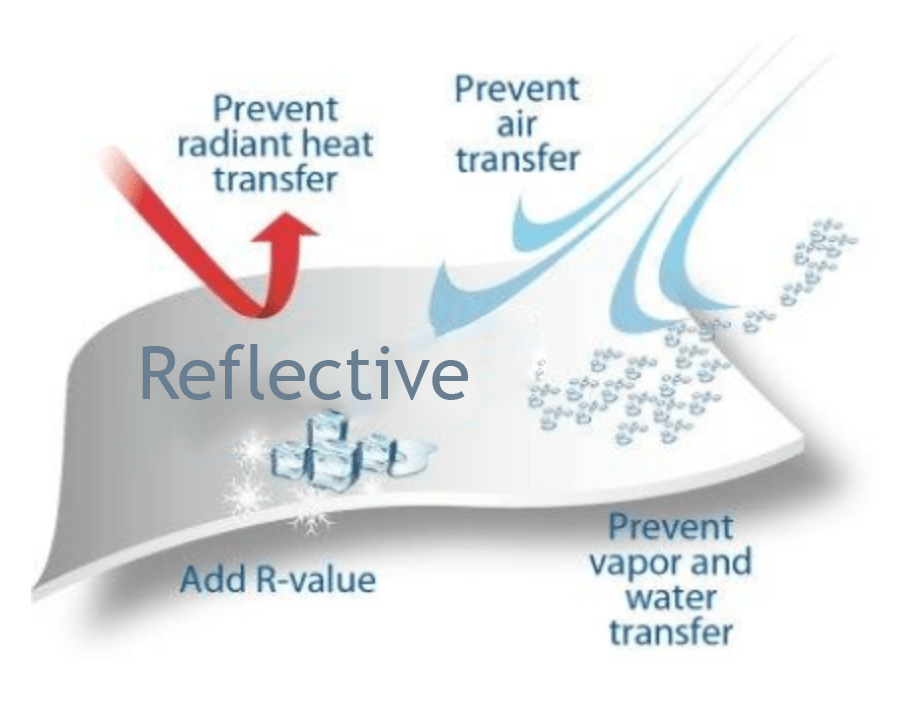

3. Vapor Barrier

Our insulation is the best vapor barrier in the industry because of its closed-cell polyethylene foam and reflective reinforced foil facing. Another advantage is our reflective insulation has no leaks because it seals around nails and screws.

4. Installation Instructions are Quick and Easy

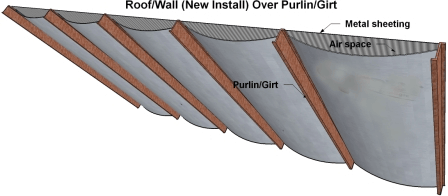

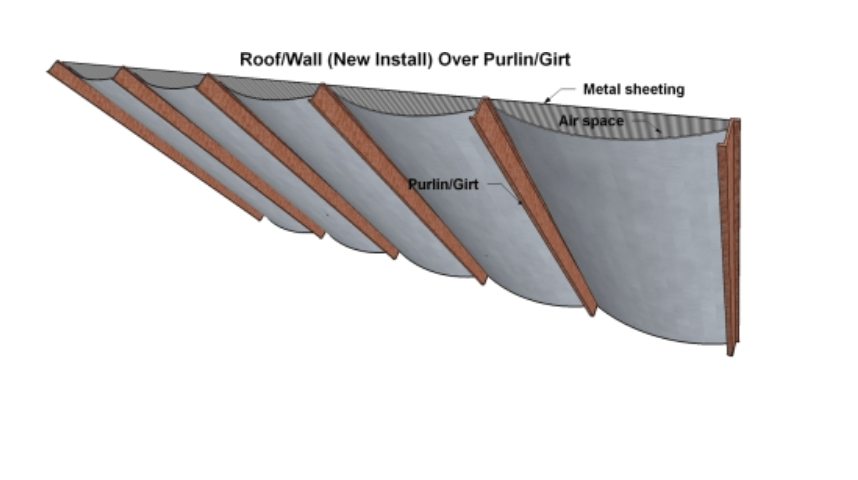

- Apply our double-sided tape on the top of the purlins. Initially applying the tape will help secure insulation – and not allow it to blow in the wind.

- Roll insulation perpendicular to and over the purlins. It would be wise to let the insulation sag 1 to 3 inches. Then seal at the seam according.

- Attach your sheeting.

5. Rodents, Bugs, and Birds can’t Nest in it

I am sorry to say that fiberglass insulation allows rodents, bugs, and birds to nest. However these creatures can’t digest foil.

6. Reduces Sounds of Rain and Hail

Have you ever been in a steel building when it rained or hailed? You would definitely remember because the metal sheeting exaggerates the sounds. Our insulation deafens the sound.

7. Air Barrier

The moisture that is carried in the air can impact the temperature and integrity of a building. The airflow within a steel building determines the spread of toxic smoke and gasses. Garages and conditioned spaces are separated by air barriers. An additional safety feature is the air barrier also acts as a gas barrier.

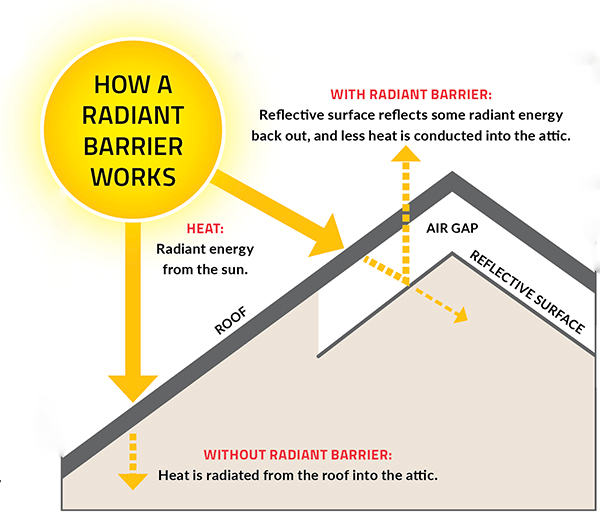

8. Stops Heat Transfer

An insulation R-value is the measurement of a material’s ability to stop heat and cold transfer. No matter what a metal building’s usage, insulating it will be of value. Because of the unique nature of a steel building, it requires a vapor barrier and a radiant barrier.

- The summer heat (sun’s rays) on a steel surface will create extreme heat temperatures inside the building.

- In addition, the cold winter temperatures are exaggerated by the metal roof and wall sheeting making it frigid inside. Warm temperatures coming in contact with cool metal roofs or walls create sweating (condensation).

CLICK, to calculate a delivered cost in 1 minute!

An insulation R-value is the measurement of a material’s ability to stop heat and cold transfer. No matter what a metal building’s usage, insulating it will be of value. Because of the unique nature of a steel building, it requires a vapor barrier and radiant barrier.

- The summer heat (sun’s rays) on a steel surface will create extreme heat temperatures inside the building.

- In addition, the cold winter temperatures are exaggerated by the metal roof and wall sheeting making it frigid inside. Warm temperatures coming in contact with cool metal roofs or walls create sweating (condensation); therefore, insulation is an imperative.

All insulation types have their niche. Factory Steel Overstock offers the two most popular insulations for Metal Buildings and Pole Barns -Fiberglass and Reflective Insulation. However, 75% of customers choose the Reflective insulation because of the EASE OF INSTALLATION, PRICE SAVINGS, AND High R- VALUES. The R-Values have been independently tested by ICC-EC. For additional information, click Reflective Resource Guide.

The #1 Selling Insulation for Steel Buildings and Pole Barns

Over a million orders of this high R-Value Reflective Insulation have been sold. This totals more than 5 million square feet of insulation!

Many in the building industry would say the most popular insulation solution for decades, whether residential, commercial, industrial, or agricultural facilities, was fiberglass insulation.

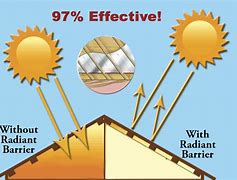

Well, this one-size-fits-all application has quickly changed! There is a quickly growing realization that the best way to slow down conductive or convective heat transfer, one needs to look to other means than fiberglass. Based on independent government studies, it is REFLECTIVE insulation that is best suited for slowing down radiant heat as well as condensation. Radiant heat can account for as much as 93% of heat transfer. Therefore, in most cases, it makes sense to use a radiant barrier instead of foam or fiberglass. Keep in mind, our reflective insulation types are not affected by humidity. This is a very important point! If there is humidity outside, there will be humidity inside your building. Your insulation must work efficiently in these conditions.

Needless to say, every type of insulation has its justified building niche. That is why Factory Steel Overstock offers the public the two most popular insulation types: Fiberglass batt and Reflective insulation. But if you primarily want to reduce radiant heat transfer, and condensation as well as save money, reflective insulation is the way to go! Our reflective is a superior and complete vapor and radiant barrier! The reflective insulation product we offer reflects the highest amount of radiant energy flow (97%) that strikes it. It reflects the heat inside the metal building in the winter and reflects the sun’s heat outward during the summer months. All of this means less cost of your heating bill, as well as lower air conditioning expenses.

High R-Value Reflective Insulation Features and Specifications

- Available High R-Value – 15.3 (white facing), 17 and 22 (reinforced reflective facing)

- It is ICC-ES Recognized

- R-Value unaffected by outside humidity

- It prevents 97% of radiant transfer (the primary source of heat flow)

- Is a vapor barrier

- Prevents condensation

- 19 dba contact noise reduction

- 90 Celsius (194 F) contact temperature rating

- UV resistance

- Center is polyethylene foam instead of air bubbles.

- Material does not allow mold or mildew

- Does not provide for nesting or rodents, bugs or birds

- Easy seals around nails (no leaks)

- 100% recyclable virgin raw materials; therefore eco -friendly.

- Its surface keeps it airflow

- Lighter weight; therefore, less cumbersome installation than fiberglass batt

- Significant price savings over fiberglass batt and spay of same R-Value standard

- Delivery times (fiberglass average delivery is 2 to 3 weeks vs. reflective is 7 to 10 days).

High R-Value 17 Reflective Insulation

It is the customer’s SOLE responsibility to verify with their local building department what certification documentation they may need BEFORE ordering insulation. Factory Steel Overstock is an independent broker, who relies on the accuracy of information supplied by the manufacturer.

- 4′ x 175′ (700′ per roll)

- Adhesive along one side of the 175′ roll.

- 5 mm thickness

- Improve tear resistance

- Flame Spread – ZERO

Insulation Layered

- Reflective reinforced foil

- Polyethlene foam

- Reflective reinforced foil

It is lightweight and easy to install. The applied adhesive running down one side of each roll makes no need to order reflective tape to seal the seam. This benefit can save up to 50% installation time. Those erecting buildings have noted its ease of installation as well as 50%-time savings.

Testimonial

I have been a part of two orders and am now working on my third order from Factory Steel Overstock. John Barber is always helpful throughout the entire process from start to finish.”

– David Muniz 30′ x 50′ x 16′ w/ R-22 Reflective Insulation

3/3/22

High R-Value Reflective Insulation – R15.3 WHITE Vinyl- BACKED

It is the customer’s SOLE responsibility to verify with their local building department what certification documentation they may need BEFORE ordering insulation. Factory Steel Overstock is an independent broker, who relies on the accuracy of information supplied by the manufacturer.

- 4′ x 175′ (700′ per roll).

- 5 mm thickness

- Improve tear resistance

- Flame Spread – ZERO

- White “attractive” facing

- Layered: Reflective reinforced foil + Polyethlene foam + UV resistant “white” facing

Insulation Layered

- Reflective reinforced foil

- Polyethlene foam

- UV resistant “white” faceing

Comparable in price to R-17 yet with the FRESH OPEN LOOK of the white vinyl backing many customers prefer in the interior of their metal building. R-Value is slightly reduced from 17 to 15.3 in this product due to the replacement of one side of polyethylene backing and reflective reinforced foil with the ALTERNATIVE UV-resistant White Facer.

Formal quotes will include double-sided tape for ease of installation.

High R-Value Reflective Insulation – R22

It is the customer’s SOLE responsibility to verify with their local building department what certification documentation they may need BEFORE ordering insulation. Factory Steel Overstock is an independent broker, who relies on the accuracy of information supplied by the manufacturer.

- 4′ X 85.3′ (341′ per roll)

- 10 mm thickness

- Increased R- Value

- Added longitudinal strength

- Improved tear resistance

- Flame Spread – ZERO

- Use a hot gun to melt the polyethlene foam at the edges overlapping rolls. Add mild pressure. This will create “very” tight connection!

Insulation Layered

- Reflective reinforce foil

- Polyethylene backing

- Close -cell polyethylene foam center

- Reflective reinforce foil

It is twice as thick as regular reflective insulation (10 mm) closed cell polyethylene foam covered on both sides with .00012 inch (0.03mm) aluminum foil facing. Its advantage is its high R-value, yet it is light and very easy to install.

Our High R-Value 22 has cuts at the edge to overlap the rolls. Overlap the rolls. Use a hot air gun to cause a welding process to occur. Simply add pressure and you will create an impermeable overlapped seal between the rolls.

Installations Steps for High R-Value Reflective Insulation:

The method you choose will determine the materials you will need:

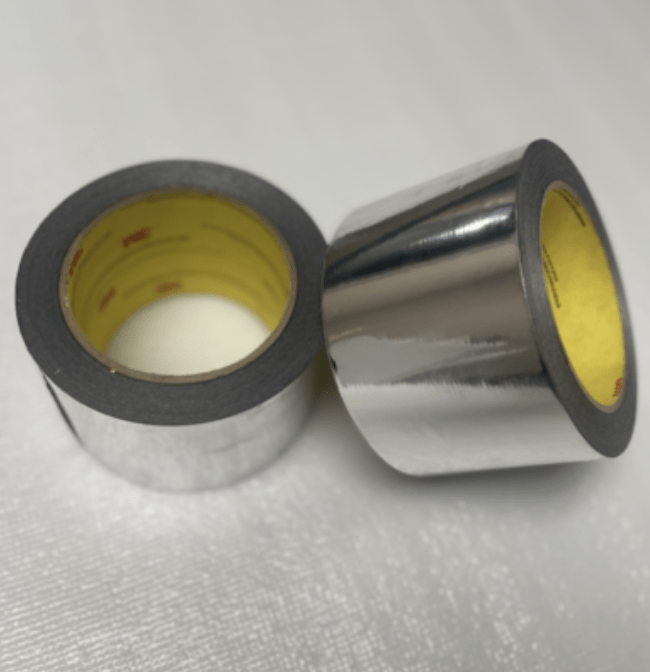

- Reflective or Double-Sided Tape

- Steel sealant

- Metal Pins and Caps

- Knife

- Heat Gun

- Reflective Tape – purpose is to seal the seams. This is applied to Reflective (White facing). It is not need with R17 because there is a adhesive already on the rolls and for R22, a heat gun is used to seal the seams.

- Double-Sided Tape purpose is to make sure the insulation doesn’t blow away during the installation process as well as helps attach insulation to the surfaces and seals seams.

- Steel Sealant – Is a super glue that is used to attached insulation with the metal pin to surfaces such as wood, aluminum, steel and much more.

- Metal Pins and Caps – Are used to attached insulation to surfaces such as wood, aluminum, steel and much more.

- Knife – To cut insulation

- Heat Gun – Purpose is to seal the seams on our R22

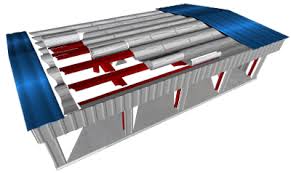

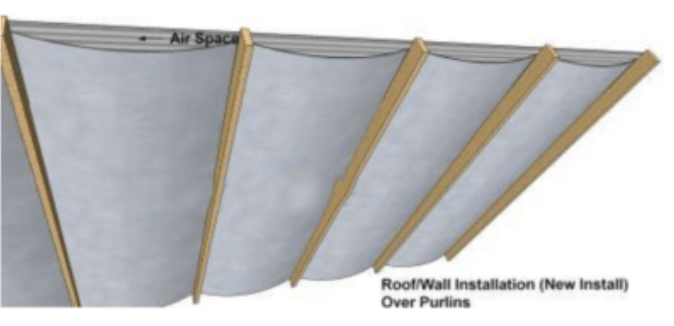

Installation Steps for New Metal Building Construction

- The first step is to apply double-sided tape on purlins to keep insulation from blowing away

- Then simply roll the insulation (whether reflective or fiberglass) perpendicular to the purlin.

- The insulation should sag approximately 2′ inches to create a air-cap.

- It is best to purchase reflective tape or double-sided tape to seal each seam. If you are purchasing our R-Value 17, it has an adhesive attached to the rolls (picture on the right); therefore, you don’t need seam tape. If you are purchasing an R-22, it seals with a Heat gun (picture in the middle).

- Lastly, attached sheeting.

Installation Steps for New Pole Barn Construction

- Apply double-sided tape on top of framing to keep insulation from blowing away.

- Then roll the insulation (whether reflective or fiberglass) perpendicular to the purlin.

- Have cap nails, screws with locking washers. Alternative is 1/2″ staples to directly attach the insulation to the wood framing.

- Again, for best performance, create a airspace of 3/4″ or more. 3/4″ furring strips are great. Another option to create an airspace is to push the insulation in a few inches.

- Again if you have purchased R 15.3 (white), tape the seam with reflective tape.

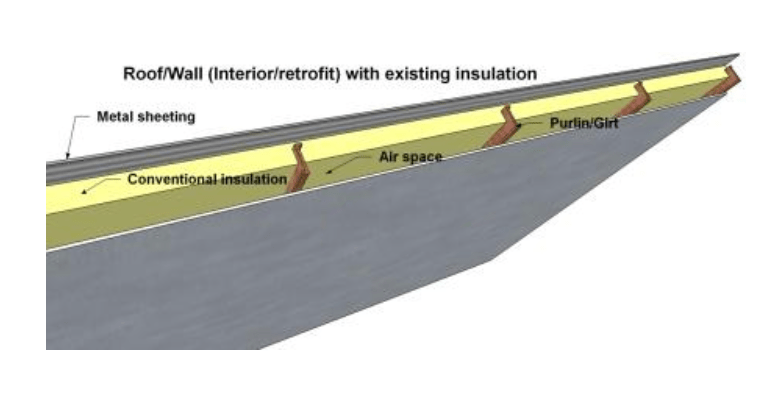

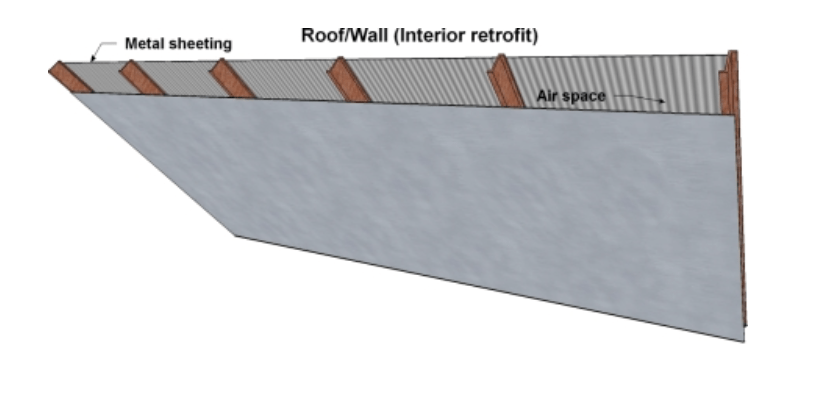

Installation Steps for Erected Steel Structures

The retrofitting instructions refer to buildings with or without prior insulation layers. It also refers to buildings that already have sheeting installed.

Tubular Installation Step

- The insulation is rolled perpendicular to the framing. Don’t be concerned about the space between the framing because the insulation is laying the opposite direction.

- The insulation is attached using self -drilling screws. We recommend 3/4″ screws with locking washers.

- If you are buying Reflective (white facing) R15.3, purchase reflective tape to seal seams. This is not needed with R22 or R17 orders. With R22, the seams are attached with a heat gun. With R17, there is adhesive attached to each roll.

I -Beam and Web Steel Structures

Two common Installation methods used below

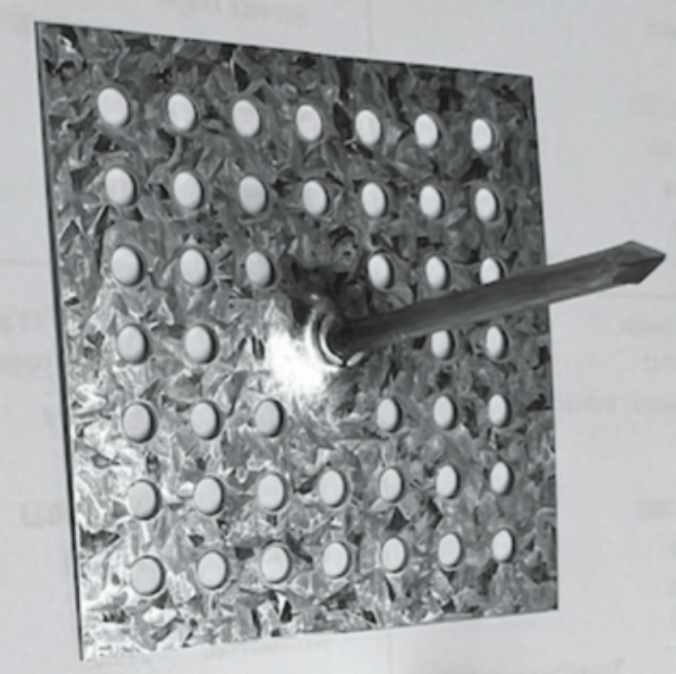

Method 1: The insulation is attached with the use of pins and caps.

Items needed: Reflective tape, Metal Sealant, Pins and caps

- Start by putting a glob of glue on base of the pin. Then press the pin on to the sheeting. Space the pins 1 every square foot. It will take approximately 24 hours for glue to fully secure.

- Push the insulation through the pin. Once done, put the cap on the pin to secure the insulation

- Then snip the end of the pins.

Method 2: Your insulation is attached with double sided and glue

- A line of glue and double side tape should run adjacent to each other on the bottom on the I-beam. The tape is a short-term hold and the glue is a longer-term hold.

For best performance, make sure to have a 3/4″ air -cap or more. Also, make sure you seal the seams.

Insulation Steps for Erected Pole Barn Structures

The retrofitting instructions refer to buildings with or without prior insulation layers. It also refers to buildings that already have sheeting installed.

Retrofitting Insulation between purlins and girts

- When attaching insulation between The Framing

Use cap nails, and screws that have locking washers. The alternative is 1/2″ stables. For best results, leave air 1″ air gap.

Summation

Temperatures can be unbearably hot and humid in the summer as well as frigid cold in winter within a steel building. Why? Well, the metal skin itself magnifies the outside heat and cold because it is the perfect conductor of it. Again, when there are temperature fluctuations from outside to inside, a steel building will sweat (condensation). So, keep your metal building perfectly cool and dry in the summer as well as warm in the winter. Best of all, do it with price savings!

The primary purpose of insulation is to keep the building cool or warm when needed. Condensation eventually will dampen fiberglass insulation and directly compromise its integrity by lessening its R-vale. Therefore, in most cases, we would recommend Reflective insulation over fiberglass when an R-value of 22 or less is sufficient or the location has a humid climate.

Buy fiberglass insulation online. Profit amount is $350.

Profit amount for Insulation Wholesale Quote is $350-$500. Steel Buildings is $1,000.

We promise to return all calls, emails, and text sent during a work week within 24 hours.

You are guaranteed a net savings below market quotes of equal specifications.