Erecting a Steel Building

Over 50% of our don’t use a metal building erector.

Here are the preliminary steps before buying and erecting a steel frame building:

- Stake out on the property where the building will reside. This will better enable you to know the right size building as well as inform you where the best locations will be for doors and window placements.

- Verify local building codes. No matter the size project, most building departments will have some code standards that must be met. Neglecting this step can result in a great deal of unneeded future expenses.

Step #1 -FOUNDATION

When starting the process of erection of a metal frame building, you must check the accuracy of anchor bolts’ size and locations. Again, since most building suppliers send out anchor bolt settings (plans) within a few weeks of building order, there should be ample time for you to get your foundation prepared before the building arrives. Factory Steel Overstock can offer certified foundation plans for the following states: WA, OR, CA, ID, NV, AZ, WY, UT, and CO.

You will receive building erection plans when your building arrives. Take the necessary time to review these plans before starting the erection process.

NOTE: Anchor Bolts are not included with the building purchase.

A metal building erector would say the foundation is unquestionably the most important part of the erecting process for a metal frame building. Unless you have direct experience pouring a foundation for a steel building, it would be wise to utilize an experienced certified foundation contractor. Likewise, you should consider this principle with erection too.

Now, if you feel you have ample general construction experience and your steel frame building kit is not large, take a stab at erecting your steel building. Many people have saved themselves considerable steel building costs doing their project with a few friends or family members; however, if your building is complex or there are strict code regulations in your area, it is best to hire a certified erector.

Step #2 – Lay Out Delivered Metal Building Frame Materials

Most building manufacturers send out Anchor bolt plans (settings) within three weeks of purchase, which will have erection sequence, proper storage, and safety information. A complete erection manual is normally sent when building materials arrive. Please refer to these documents for more detailed instructions before erecting a steel building.

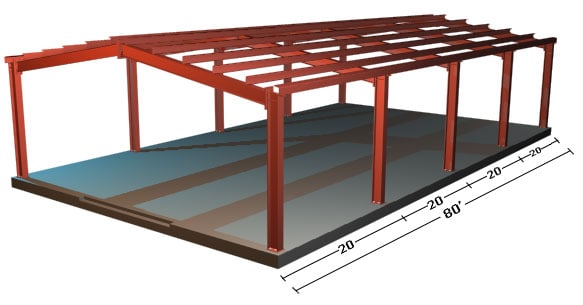

Layout your steel frame building materials properly around the foundation. Place the columns and rafters at whatever end you intend to start. You will move them with your crane to their permanent locations. Put sheeting bundles on wood blocks around the foundation as close as possible to where they will be installed. Then lay out trims sheeting panels, and insulation in a location out of the way. These items will be the last items installed.

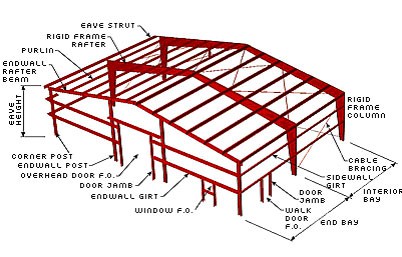

Step #3 – MAIN FRAMES PURLINS AND GIRTS

You will stand your mainframe and rafters into place first. These members should be pre-cut, punched, and welded. Because they are your heaviest items, you will utilize your crane for their movement and placement. They will bolt together and be fastened to your foundation. Then you will install your secondary members (purlins and girts).

Step #4 – INSTALL FRAMED OPENINGS

When you are installing girts, you will also install factory-located framed openings and accessory framed openings to which the girts attach to.

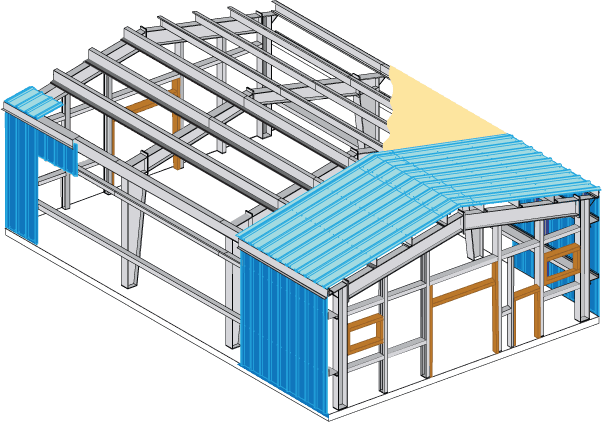

Step #5 – Roof & Wall Sheeting

You are halfway done. Like a professional metal building erector, you will now focus your attention on installing wall and roof sheeting. Start with the walls and screw the sheeting into the frames with the fasteners supplied. Then do the same process with the roof sheeting. The screws should be snug. All the certified steel building suppliers supply weather stripping to be applied between the panels. You will also install insulation at this time if it is ordered.

Step #6 – Installing Accessories

You will now install trim that not only beautifies your steel frame building, it also protects your building by sealing it. You will also install any accessories such as windows, walk doors, louvers, etc.

Satisfied Customers Who Built it Themselves…

“We love our steel building. We erected it ourselves. Thank you Factory Steel Overstock.”

– Gerald J 50 x 60 x 16

“Probably saved 30k between using your company and erecting the building ourselves. Would definitely recommend you to anyone.

Thank you soooooooooo much!”

Ron & Kelly O.

Cost-Plus Program Made Simple

A 35-year industry veteran presents a spiritual approach by allowing those prepared to give back TODAY a wholesale quote without an upfront cost.

- Review 1 to 3 market quotes as well as our posted insulation prices and steel building prices.

- Fill out one of these forms: Name Your Price, Wholesale Metal Building Quote, and Wholesale Insulation Quote.

- Call 1-888-512-1116 to let a representative know you submitted a form and to go over the details submitted.

- After the quoted savings, pay the low service fee that SAME DAY: $350-$500 Insulation orders – $750-$1,500 Steel Building orders.

- For a full process, click – Order To Delivery

- Reflective insulation is delivered in 7-10 days. Receive Order #. Ships the next day! Receive a call from the shipper before delivery.

- Fiberglass insulation is delivered in 2-3 weeks. Receive Order #. Receive a call from the shipper before delivery.

- Steel Building Kits are delivered in 8-10 weeks. Receive the Order # and Scheduling information. Certified plans completed within 4 weeks. Receive a call from the shipper before delivery.

With Factory Steel Overstock, you take control from the start by Naming Your Price

Smart buyers utilize a transparent Wholesale Cost-plus programs over traditional retail outlets.

We promise to return all calls, emails, and text sent during a work week within 24 hours.

We are so confident in our efforts, that we are willing to give you back our fee if you don’t receive the services noted

You are guaranteed a net savings below market quotes of equal specifications.

Helpful Links

Click for More Testimonials

“Faith is taking the first step even when you don’t see the whole staircase.” Martin Luther King

Client Testimonials

“I ordered three buildings and this has been an excellent experience. The website is extremely helpful for planning purposes. The order process is efficient and the staff is very efficient and helpful. I have already recommended FSO to a friend.”

– 50x100x16 Connie C. 7/2/2018

“Definitely will do business with this company again.”

– by Ivan Timoshuchuk 10/9/2021

“I have purchased and erected four metal buildings in the past. This transaction was the best price by far and the simplest person to deal with. He never tried to constantly up sell me. All my buildings in the future will come from Factory Steel Overstock.”

– by Ralph B. 75 x 90 x 18

– Feb. 06, 2015