Metal Building Roll-Up Doors

Finally, there is a company that quotes metal building roll-up doors at wholesale prices

Roll Up Doors for Metal Buildings

As a rule of thumb, choose your Roll-Up door to be 2′ less than building height & 2′ clearance right & left bay column on SIDEWALLS when ordering building with FSO.

For ENDWALLS placement of doors, the building should be at least 2.5′ taller than door height in 1:12 roof pitch, due to interior building framing components. Plan 3-4′ less than eave height and sides if your building requires a Portal Frame. FSO representative will confirm that your chosen door size fits at the time of building order.

Roll Up Door Sizes and Headroom for Chain Hoist Operated Doors:

Series 2750 and under: Need 22″ (UP TO 10′ tall doors), Need 24″ (10′-14′ tall doors), Need 26″ (Over 14′ tall doors)

Series 5000: Need 22″ (UP TO 10′ tall doors), Need 24″ (10′-14′ tall doors), Need 26″ (Through 16′ tall doors) , Need 28″ (Through 20′ tall doors)

1900 Series Non-Insulated & 1950 Series Insulated Roll Up Doors

Light-duty: non-wind rated: These doors are the most economical roll-up doors for light use. The light-duty commercial door utilizes 9 1/2″ drums instead of the standard 12″ drum, requiring less headroom during installation.

Click Here for More 1900 Series & 1950 Series Specifications

Curtain

- 26-gauge galvanized, Grade E hard steel

- 5/8″ ribbed corrugation

- Max opening size 12′ x 14′

- Siliconized polyester WeatherXL™ paint over prime coat

Bottom Bar

- 6063 – T6 aluminum extrusion

- 2″ x 1 1/2″ galvanized angles

- Bulb astragal

- Stainless steel nuts and bolts

Axle-Drum Assembly

- 1 5/16″ O.D. steel axle, 14-gauge

- 11-gauge axle on doors

- Oil tempered torsion springs

- Utilizes 9 1/2″, 18-gauge drums

- Shielded steel ball bearings in drums

A.C.E. (Advanced Curtain Engagement) Guide System

- Galvanized steel

- Adjustable bolt on head stop

- Polyethylene wear strip

- Pre-punched holes for lock and attachment fasteners

Hardware

- 13-gauge saddle clamps

- 10-gauge slide locks, two per door

- 16-gauge step plate; two per door

- 1/4″ steel angle T-bracket

2000 Series Non-Insulated & 2250 Series Insulated

Light-duty: non-wind rated: These doors are ideal for warehouses, car washes, machine shops, auto body shops and more.

Click Here for More 2000 Series & 2250 Series Specifications

Curtain

- 26-gauge galvanized, Grade E hard steel

- 5/8″ ribbed corrugation

- Max opening size 12′ x 18′

- Siliconized polyester WeatherXL paint over prime coat

Bottom Bar

- 6063 – T6 aluminum extrusion

- 2″ x 1 1/2″ galvanized angles

- Bulb astragal

- Stainless steel nuts and bolts

Axle-Drum Assembly

- 1 5/16″ O.D. steel axle, 14-gauge

- 11-gauge axle on doors over 10′ wide

- Utilizes 12″, 16-gauge drums

- Shielded steel ball bearings in drums

A.C.E. (Advanced Curtain Engagement) Guide System

- 16-gauge galvanized steel

- Adjustable bolt on head stop

- Polyethylene wear strip

- Pre-punched holes for lock and attachment fasteners

Hardware

- Saddle clamps with set fasteners

- 10-gauge slide locks, two per door

- 16-gauge step plate; two per door

- 1/4″ steel angle T-bracket

2500 Series Non-Insulated & 2750 Series Insulated

Heavy-duty: Wind Rated up to 12′: This door has deep engagement guides creating greater durability and stronger, longer-lasting performance. These doors operate with ease under heavy-duty use such as warehouse and loading docks.

Click Here for More 2500 Series & 2750 Series Specifications

Curtain

- 26-gauge galvanized, Grade E hard steel

- 5/8″ ribbed corrugation

- Max opening size 18′ x 18′

- Siliconized polyester WeatherXL™ paint over prime coat

Bottom Bar

- 6063 – T6 aluminum extrusion

- 2″ x 1 1/2″ galvanized angles

- Bulb astragal

- Stainless steel nuts and bolts

Axle-Drum Assembly

- 1 5/16″ O.D. steel axle, 14-gauge

- 11-gauge axle on doors over 10′ wide

- Utilizes 12″, 16-gauge drums

- Shielded steel ball bearings in drums

- Oil tempered torsion springs

A.C.E. (Advanced Curtain Engagement) Guide System

- 14-gauge galvanized steel

- Adjustable bolt on head stop

- Polyethylene wear strip

- Pre-punched holes for lock and attachment fasteners

Hardware

- Saddle clamps with set fasteners

- 10-gauge slide locks, two per door

- 16-gauge step plate; two per door

- 1/4″ steel angle T-bracket

- Aluminum “T” shaped lead stop

5000 Series Non-Insulated & 5250 Series Insulated

Heavy-duty: High Wind Rated: Built to stand up to strong winds caused by tornadoes and hurricanes for years with little-to-no maintenance, the durable 5000 Series door meets the stringent building codes of many coastal areas. Features include deep engagement guides and side curtain “J” shaped windlocks to maintain the operational integrity of the door and comply with most state and local building codes

Series 5000: Need 22″ (UP TO 10′ tall doors), Need 24″ (10′-14′ tall doors), Need 26″ (Through 16′ tall doors) , Need 28″ (Through 20′ tall doors)

Click Here for More 5000 & 5250 Series Specifications

Curtain

- 26-gauge galvanized, Grade E hard steel

- 5/8″ ribbed corrugation with three-rivet windlock attachment

- Max opening size 18′ x 16′

- Siliconized polyester WeatherXL paint over prime coat

Bottom Bar

- 6063 – T6 aluminum extrusion

- 2″ x 1 1/2″ galvanized angles

- Bulb astragal

- Stainless steel nuts and bolts

Axle-Drum Assembly

- 1 5/16″ O.D. steel axle, 14-gauge

- 11-gauge axle on doors over 10′ wide

- Utilizes 12″, 16-gauge drums

- Shielded steel ball bearings in drums

- Oil tempered torsion springs

A.C.E. (Advanced Curtain Engagement) Guide System

- 12-gauge galvanized steel

- 12-gauge wind lock bar

- Adjustable bolt on head stop

- Polyethylene wear strip

- Pre-punched holes for lock and attachment fasteners

Hardware

- Saddle clamps with set fasteners

- 10-gauge slide locks, two per door

- 16-gauge step plate; two per door

- 1/4″ steel angle T-bracket

General Information for Roll Up Doors

Click for More General Information for Roll Up Doors

Our commercial doors use heavy-duty brackets made of .187-thick angle, as well as have a high-cycle spring life and continuous-duty design. The commercial doors are wind load tested in accordance with IBC, FBC and TDI. Furthermore, our metal building roll up doors have electric motor capabilities and multiple mounting options including steel, wood, masonry, and concrete.

These steel curtain roll-up doors are easy to install and, additionally require minimal maintenance. We have a variety of models and colors available from which to choose.

Curtain

Notice that our commercial doors are manufactured with hard, Grade E steel ensuring strength and durability. A siliconized polyester finish replaces older polyester paint finishes, which are recognizable by severe chalking and fading from direct contact with UV rays and, in summary, our steel curtain roll-up doors are coated with a silicone polyester paint highly resistant to UV light rays allowing some colors a warranty of up to 25 years.

- 26-gauge galvanized, Grade E hard steel

- 5/8″ ribbed corrugation

- Siliconized polyester WeatherXL™ paint over prime coat

- 30-year film integrity warranty, up to 25-year chalk and fade warranty

A.C.E. Guides System

Notice that the A.C.E. (Advanced Curtain Engagement) guide system has been designed to benefit our customers. Some of the benefits include universal mounting options, increased durability, excellent performance and ease of installation. These doors are of the most advanced rolling sheet door guide systems in the industry.

Axle-Drum Assembly

The commercial door axles and drums are manufactured with industrial-grade steel. The door drums are designed and engineered specifically for commercial application to ensure product integrity, long life, and high-capacity use. Steel ball bearings are preferable to nylon or plastic bushings, which can disintegrate under heavy use.

Springs

The springs are the most critical mechanical component of a steel curtain roll-up door. For maximum reliability, the manufacturer uses only oil-tempered torsion-type springs for its commercial-grade steel curtain roll up doors. Coordinating the design of a roll-up door with the proper spring assembly ensures longer and more durable use with minimal maintenance required. In independent tests, our commercial-grade steel curtain roll-up door exceeded 40,000 openings and closings before any maintenance was required. Although there is no such thing as a maintenance-free door, we engineer our roll-up doors to be maintenance-simple: easily visible for inspection and accessibility.

Wind Load Certification

Fueled by the constant changes in local and national building codes, as well as increasing insurance costs, choosing a door with a validated wind certification can dramatically reduce maintenance and replacement costs. The in-house wind certification facility enables us to manufacture doors to the highest standards. Our commercial door 5000 Series, wind certified doors are designed to meet stringent building codes in coastal regions and Florida.

Installation

Always follow the manufacturer’s installation guide to avoid injury to self, others or your property!

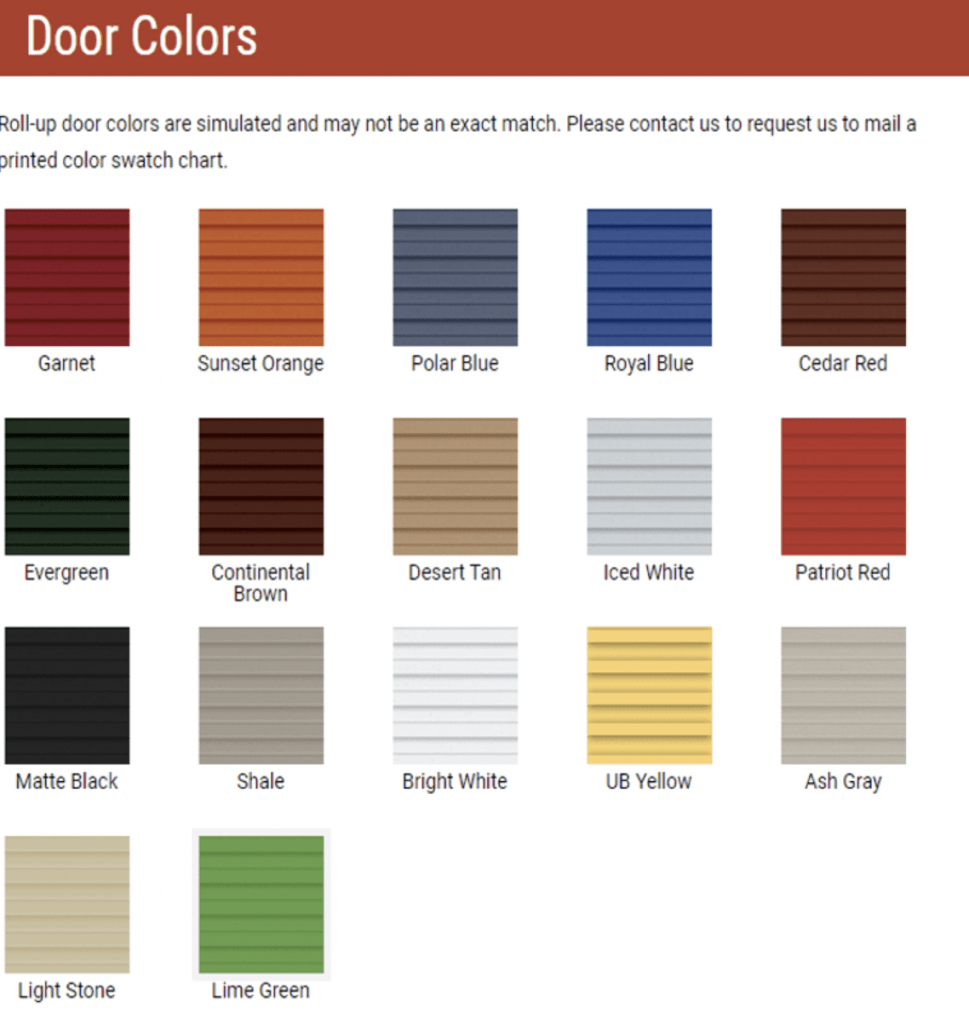

Choice of Colors for Roll Up Doors

Some non-standard colors may require a bit of lead time to order.

Cost-Plus Program Made Simple

A 35-year industry veteran presents a spiritual approach by allowing those prepared to give back TODAY a wholesale quote without an upfront cost.

- Review 1 to 3 market quotes as well as our posted insulation prices and steel building prices.

- Fill out one of these forms: Name Your Price, Wholesale Metal Building Quote, and Wholesale Insulation Quote.

- Call 1-888-512-1116 to let a representative know you submitted a form and to go over the details submitted.

- After the quoted savings, pay the low service fee that SAME DAY: $350-$500 Insulation orders – $750-$1,500 Steel Building orders.

- For a full process, click – Order To Delivery

- Reflective insulation is delivered in 7-10 days. Receive Order #. Ships the next day! Receive a call from the shipper before delivery.

- Fiberglass insulation is delivered in 2-3 weeks. Receive Order #. Receive a call from the shipper before delivery.

- Steel Building Kits are delivered in 8-10 weeks. Receive the Order # and Scheduling information. Certified plans completed within 4 weeks. Receive a call from the shipper before delivery.

With Factory Steel Overstock, you take control from the start by Naming Your Price

Smart buyers utilize a transparent Wholesale Cost-plus programs over traditional retail outlets.

We promise to return all calls, emails, and text sent during a work week within 24 hours.

We are so confident in our efforts, that we are willing to give you back our fee if you don’t receive the services noted

You are guaranteed a net savings below market quotes of equal specifications.