Below, the general public can calculate certified low-cost fiberglass insulation prices. After reviewing prices, decide to buy online or get a wholesale quote. Question, 1-888-512-1116.

Cheap Fiberglass Insulation Prices

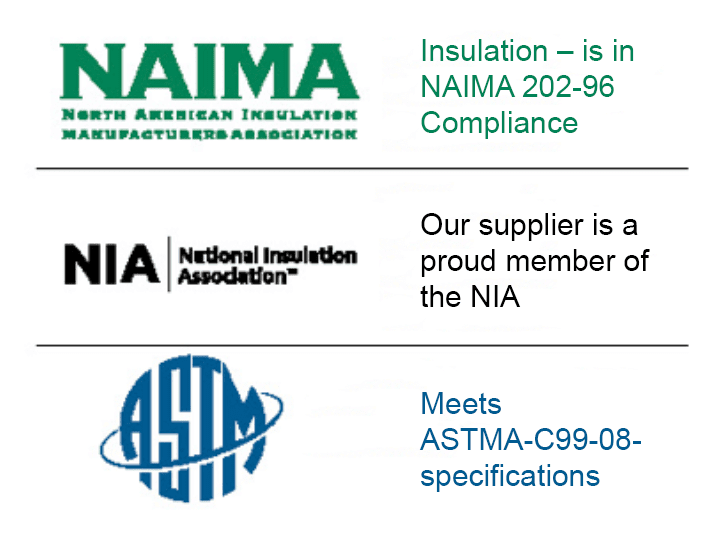

Amidst the challenging search for low-cost fiberglass insulation prices, often complicated by commission salespeople pushing for the highest possible profits, Factory Steel Overstock has emerged as a reliable source since its inception in 2011. A quick comparison of FSO’ prices will confirm that it offers certified NAIMA, NIA, and ASTM fiberglass insulation at the best rates.

Order Insulation Online

You can order insulation online in minutes. Not only can you review low-cost fiberglass insulation pricing, you can review features, specifications, and installation information within the tabs below.

Again, once you’ve calculated your delivered price, decide whether you want to buy fiberglass insulation online or receive a custom quote. It’s that simple to get certified and cheap fiberglass insulation prices. Factory Steel Overstock-your Fiberglass Insulation Specialist!

Order Insulation Online and Save!

Order was easy to place and the product arrived when it was supposed to. Will be buying from them again. – Ms. Cummings.

Click Video for information on Low-Cost Fiberglass Insulation and Cost-Plus program

Buy Fiberglass Insulation Online Now

- In the Online Calculator above, after you see your wholesale delivered price, click the Buy Now button. You will taken to the Payment Center Page

- On the Payment Center page, click Buy Now button again. Pay the brokerage fee that corresponds to wholesale delivered cost. Cost -Plus Fee Chart below

- Call 1-888-512-1116 to to inform our representative that paid the brokerage fee. You will be emailed a comprehensive proposal.

- Then you will receive order # and direction for you to complete payment with certified supplier..

| Fiberglass Insulation Wholesale Delivered Cost | Buy Online Brokerage Fee | Quoted Orders Brokerage Fee |

| $0 – $1,000 | $175 | $275 |

| $1,001 – $3,000 | $300 | $400 |

| $3,001 – $5,000* | $400* | $500 |

| $5,001 – $7,000 | $500 | $600 |

| $7,001- $10,000 | $600 | $750 |

| $10,001 – $15,000 | $750 | $850 |

| $15,001 – $20,000 | $850 | $1,000 |

Though we offer cheap fiberglass insulation prices, we offer all the options!

- VR

- VRR+ (Standard Offer)

- WMP-10

- WMP – 30

- WMP-50′

- Unfaced

- Black Color Facing

- White Color Facing

Your Low-Cost Fiberglass Insulation Proposal will include:

- Type of insulation (example- VR-R +)

- Number of rolls

- Width of rolls

- Length of rolls

- Total square ft of insulation

- Estimated Weight

- Volume in cu ft

- Thickness of insulation

- R-Value

- Tax rate

- Delivered cost

Features of Low-Cost Fiberglass Insulation made in the USA

Steel building insulation is basically blankets of woven long-strand fiberglass that are laminated on one side to a vapor-barrier facing. Facing materials are applied to fiberglass insulation blankets to serve as a vapor retarder as well as a protected cover over the fiberglass.

- Our wholesale priced fiberglass insulation has a standard 3″ tab runs along both sides of rolled-out insulation for easier handling during installation. You can request a 6″ tab

- Double face tape and patch is a standard inclusion on insulation quoted by building measurements. If the quote is for a specific square ft of insulation, then the patch, and double-face tapes are added upon request. You see, FSO doesn’t arbitrarily add expenses without your permission.

- Customers can indicate the cut length of their rolls. This option applies to fiberglass insulation online orders too.

- Standard fiberglass insulation widths: 3′, 4′, 5′, and 6′.

- Factory Steel Overstock standard quotes include a stronger VR-R “PLUS” facing instead of the industry-standard VR-R.

With our cost-plus program, you pay only $350 above the wholesale cost. That’s what you call CHEAP FIBERGLASS INSULATION!

Reasons to purchase our Cheap Fiberglass Insulation

- Thermal Efficiency

- Cost-Effectiveness

- Ease of Installation

- Sound Dampening

- Vapor Retard Protection is Moisture Resistant

- It is NIA, NAIMA, and ASTM certified

For more information, click Fiberglass Resource Guide

Our Low-Cost Fiberglass Insulation Prices reflect these certifications.

Why pay more for the exact specifications, certifications, and materials originating at the same plants?

Fiberglass Faced Insulation (made in the USA) is in Naima 202-96 compliance

This is an independent test performed by Home Innovations. When the facing is laminated to the fiberglass it crushes the fiberglass. The test ensures that after manufacturing the product unrolls to the specified R-value. Some manufacturers do not want to pay for this test and say they do in-house testing. In these cases, the product often hits the field from these manufacturers which is less than performance. With NAIMA 202-96 fiberglass guarantee you get the R-value you ask for.

An additional standards met or exceeded:

- ASTM C991-08, Standard Specification for Flexible

Fibrous Glass Insulation for Metal Buildings; Type II.

NIA Compliance

Our low-cost fiberglass insulation meets NIA standards. This means that the product or installation follows the guidelines set by the National Insulation Association. These standards ensure that insulation materials and methods are safe, efficient, and effective, leading to better energy conservation, reduced energy costs, and adherence to industry best practices for quality and environmental sustainability. Compliance signifies a commitment to maintaining high performance and reliability in insulation projects.

Unfaced Low-Cost Fiberglass Insulation Blanket

Description

Our unfaced insulation is a light density blanket

of fiberglass. Its purpose is to add to the structure’s thermal

performance as a backfill insulation in various insulation

systems or in combination with an interior layer of faced metal

building insulation.

Factory Steel Overstock’s unfaced low-cot fiberglass insulation is designed for use on the

roof or in the wall system of metal buildings and pole barns.

Protecting Your Insulation Moisture

Our low-cost Fiberglass Batt Insulation will not sustain mold growth like aspergillus niger, aspergillus avus, aspergillus versicolor, penicillium, and chaetomium globosum . Needless to say, mold can grow on almost any material when it becomes wet and contaminated. Therefore it behooves you to inspect any insulation that has been exposed to water. If you notice any sign of mold, immediately discarded the insulation. If your insulation is but not showing evidence of mold, simply dry it thoroughly. Finally, if your insulation facing shows signs of

degradation from moisture, replaced it immediately.

| R-Values | Nominal Thickness | Available Widths | Available Length |

| R-8 | 2 ½” | 36”, 48”, 60”, 72” | N/A |

| R-10 | 3 ¼” | 36”, 48”, 60”, 72” | 100′ |

| R-11 | 3 ½” | 36”, 48”, 60”, 72” | 90′ |

| R-12 | 3 ½” | 36”, 48”, 60”, 72” | N/A |

| R-13 | 4 ¼” | 36”, 48”, 60”, 72” | 80′ |

| R-16 | 5″ | 36”, 48”, 60”, 72”,93”, 96” | N/A |

| R-19 | 6” | 36”, 48”, 60”, 72” | 55′ |

| R-20 | 6” | 36”, 48”, 60”, 72” | N/A |

| R-21 | 6 ¾” | 36”, 48”, 60”, 72” | N/A |

| R-25 | 8” | 36”, 48”, 60”, 72” | 40′ |

| R-28 | 8” | 36”, 48”, 60”, 72” | N/A |

| R-30 | 9 ¼” | 36”, 48”, 60”, 72” | N/A |

For more information, click Fiberglass Resource Guide

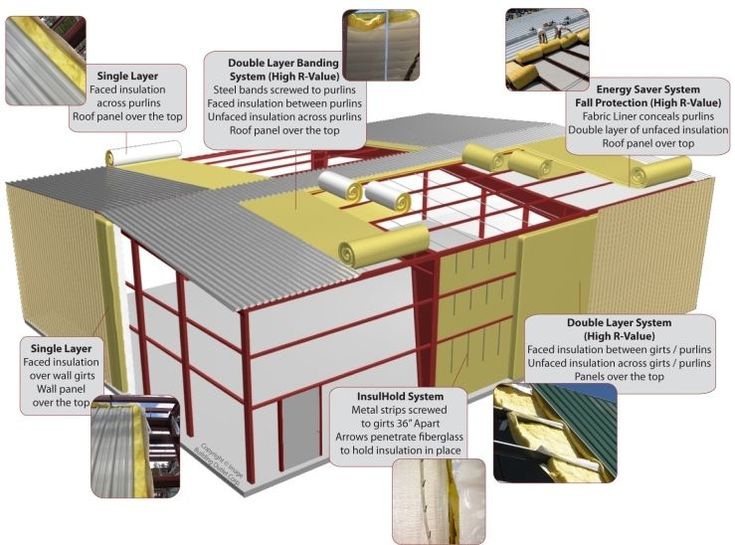

Vinyl-faced Fiberglass Insulation secured between sheeting and purlins.

Factory Steel Overstock offers Low-cost Fiberglass fiberglass insulation to the general public.

Cheap fiberglass Insulation between purlins/girts. Unfaced insulation across purlins/girts.

Installing Single Layer Fiberglass Insulation

Not only is our fiberglass insulation affordable, the material is easy to install.

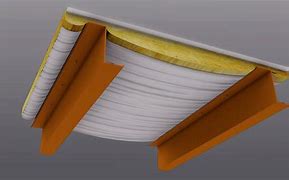

First remove dust and debris from the steel members so that you can apply double-sided tape firmly to the frames. The tape is required to hold the insulation firmly to the frames while you install the rolls. Then you measure the amount of tape you will need and cut the tape accordingly. Peel off the paper backing attached to one side of the tape, then firmly press the tape onto the metal building. Then, peel off the other side of the paper backing and press the fiberglass insulation onto the tape. Make sure there is a tight bond. Obviously, you will repeat this step until you have complete coverage.

To install the insulation, unroll it across the roof purlins or wall girts before putting up the exterior metal sheets. The insulation roll forms a layer trapped between the metal on the inside and the outer sheeting.

The fiberglass insulation is effectively squeezed between the inner metal surface and the outer shell. The vapor barrier, which typically has a white finish, should face the interior of the building, offering a neat and tidy appearance once installed. We make sure this facing is reinforced for added durability, ensuring our customers receive the strongest support possible. Using this method, you can attain insulation values up to R-19 with just a single layer.

The installation includes 3-inch tabs that should be folded over and stapled into place. Most order double-sided tape for straightforward application to the structure, along with a small amount of patch tape to fix any small rips that might occur. This insulation also applies with foil faced fiberglass insulation too. Order our affordable fiberglass insulation now!

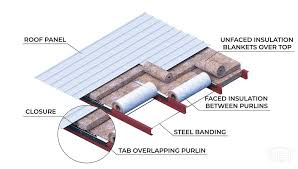

Installing a Double Layer Fiberglass Insulation System

You will start by competing the taping process written above in the first paragraph.

One of the advantages of using fiberglass insulation is its flexibility in enhancing insulation effectiveness by adding another layer, thereby improving its R-value. The maximum R-value achievable with a single layer is R-19, which corresponds to a thickness of 6 inches. The depth of your purlins will guide the thickness choice for the initial layer.

We provide rolls of faced fiberglass insulation, always ensuring they come with a reinforced backing for extra durability, which are set into the spaces between the purlins or girts. This setup is crucial as it leverages the cavity space to boost insulation performance.

The first layer of insulation is kept in place with bands attached to the purlins’ underside. Then, a second layer of unfaced insulation is laid across the top of these purlins or girts, establishing a dual-layer insulation arrangement that significantly increases the R-value. The best part, you can buy at cheap fiberglass insulation prices online.

Below is a photo with installation guides.