Metal Building Insulation

Calculate the wholesale Metal Building Insulation price yourself! Then determine the profit amount for Factory Steel Overstock.

The public prefers Metal Building Insulation Rolls over spray foam insulation because they are more cost-effective, especially for buildings with wide spans that require coverage. It is much easier to install than spray foam, which requires specialized equipment and training. This makes it the perfect choice for do-it-yourselfers who want their pole barns or metal buildings to have thermal and vapor barrier protection. By the way, metal building insulation rolls should have a protective, tear-resistant, and built-in vapor barrier facing. This is not a standard feature for spray foam insulation.

Factory Steel Overstock uniquely empowers the general public to not only calculate the actual wholesale cost for certified NIA, NAIMA, and ASTM-compliant metal building insulation rolls, but also allows the public to recommend the profit amount, instead of relying on commission-based salespeople.

- Calculate a metal building insulation roll delivered price.

- Fill out an Order Form (write the offered profit amount the form).

- If you are offered a common amount, pay it.

- Customers receive instructions for paying balances to certified supliers

- Expedited shipping takes 3-10 days. Standard Shipping is 11-21 days.

Video: How to Order Metal Building Insulation

Metal Building Insulation Rolls

Most construction projects require fiberglass metal building insulation rolls that are pre-cut to fit between structural members. Generally speaking, before fiberglass insulation is cut, it is referred to as rolls or blankets. Once cut, it is referenced as batts. In most cases, the insulation is cut to some degree for public use, as uncut metal building insulation rolls would be heavy to lift. The facings added to the insulation rolls or blankets serve as a vapor retarder, providing additional moisture control. Since condensation is a significant issue with metal buildings, these facings protect the structure from rust, mold growth, and future structural problems.

You want a continuous, unobstructed insulation barrier and a seamless layer covering the entire metal building structure. If not, you will lose thermal efficiency, and condensation issues may still occur. Fiberglass metal building insulation rolls are the ideal item for creating this needed protection. Fiberglass vinyl insulation rolls minimize heat transfer, allowing the interior of your structure to remain comfortable even in fluctuating external temperatures. Consequently, everyone within the structure experiences consistent warmth during the winter and refreshing coolness in the summer. What does all this add up to? Decreased reliance on heating and cooling systems results in significant energy savings and lower utility bills, which everyone wants.

Fiberglass metal building Insulation rolls are critical in enhancing the performance and comfortability of your metal structure, pole barns, or agricultural shop. Whether it’s a riding arena, cold storage structure, or industrial shop, selecting the correct metal building insulation is vital to the building’s efficiency and structural integrity. This page highlights the various types of insulation, their importance, and a wide variety of metal building insulation prices. Moreover, I will highlight the benefits of saving money through energy efficiency, maintaining the desired temperature, reducing condensation, and improving soundproofing.

Save Money with Energy Efficiency

Let’s be pragmatic here: We are all interested in how to save money. Again, fiberglass metal building insulation rolls save money because they reduce your heating and cooling costs.

Since many people may be unaware that metal building sheeting is a highly conductive material, I believe it is necessary to elaborate on this issue. Although this might seem counterintuitive, cold outside temperatures will be as cold or colder inside a metal structure. Therefore, substantial heat loss will occur without proper metal building insulation rolls. Likewise, the conductive nature of the metal skin can lead to excessive heat gain within a building, as it heats up and acts like a stove. A wise consumer installs the proper metal building insulation rolls, which act as a radiant, air, and condensation barrier, requiring less energy to heat or cool the building. We all want a consistent indoor temperature as well as reduced energy bills.

Please remember to review our metal building insulation roll prices using the Fiberglass Insulation Wholesale Calculator on this webpage.

Maintain Desired Temperature

When we come in from a cold or a hot day, we all desire a particular comfortable temperature within our structures. This is the primary reason people desire fiberglass metal building insulation rolls . Insulation directly contributes to the comfort levels inside structures. Based on the R-value (measurement of the effectiveness of protecting the building), the insulation affects the exchange of heat or cold through the walls and roof. Consequently, insulation helps stabilize indoor temperature regardless of external weather conditions. This helps create and maintain the desired temperature year-round.

Curtailing Condensation

Metal buildings and pole barns sweat. This is a fact that shouldn’t be ignored. Sweat is called condensation. Condensation is a common phenomenon that occurs under specific weather conditions. Some refer to it as the dew point within a building envelope. It occurs when moist air inside the building interacts with the cold skin of the uninsulated metal sheets. Water droplets form. This can lead to potential damage, including rust, mold, and mildew, over time. Properly installed metal building insulation helps control this condensation by keeping the metal skin at the desired temperature. Moreover, protecting the building from rust, mold, and mildew has health benefits. Furthermore, insulation also increases the longevity of a structure.

Sound Dampening

If you’ve been in an uninsulated metal building or pole barn during a rainstorm, you know it sounds similar to a plane taking off. Metal structures are known for being quite noisy, mainly when industrial machinery is in operation or during heavy rain and hailstorms. Sound waves quickly reverberate through metal sheeting, which can amplify noise to the point where it becomes unbearable for occupants. Metal building insulation rolls are an effective sound-dampening agent because they absorb sound vibrations. Securing the proper insulation for structures such as churches, schools, libraries, residences, office buildings, and hospitals is crucial for maintaining hearing, concentration, and overall well-being within these establishments.

We can summarize by stating that a vapor barrier is vital. It provides sound dampening, energy efficiency, and the needed tear resistance. It is the one investment that pays for itself. Selecting and installing the correct metal building insulation is one of the most crucial aspects of any new construction project.

Now that we understand the effectiveness of metal building insulation in reducing heat flow, condensation, and enhancing energy efficiency, let’s examine the various insulation products and methods commonly selected. These would include fiberglass, reflective (radiant barrier), rigid foam, and spray foam.

Buy Fiberglass Insulation Online

On this page, you can buy fiberglass insulation online at wholesale rates. With Factory Steel Overstock’s cost-plus program, you are in control of the process—there is no haggling or up-charging! Factory Steel Overstock has the only fair program for determining the added profit above the listed wholesale price. The speed, ease, and size of the order determine the amount of added profit.

- Fiberglass Insulation

Fiberglass insulation, often called “Batt” insulation, is made from fine glass fibers and is still the most popular insulation for metal buildings. It is the preferred choice because of its cost-effectiveness and thermal resistance qualities.

- Positive Features: effective sound dampening and you can easily buy fiberglass insulation online.

- Negative Features: When installing, one needs to wear protective gear due to the risk of irritation. Additionally, the R-value may decrease over time due to moisture absorption if you do not have a vapor barrier and a tear-resistant facing. With FSO, you can by fiberglass insulation online with any of the popular protective facings.

2. Reflective Insulation

Reflective insulation, or radiant barrier insulation, has become a popular metal building insulation type because it effectively reflects radiant heat away from the metal building or pole barn. It is not affected by moisture, making it uniquely effective in hot or humid climates.

- Positive Features: As an excellent radiant barrier, it reflects heat away, reducing energy costs during the warm months. Additionally, it is lightweight and easy to install.

- Negative Features: It is not effective in very cold climates, and it is often selected for warmer, humid locations. It requires an air gap to reach its listed R-value; therefore, proper installation is key. It is an insulation to complement fiberglass-reinforced faced insulation. It should never be selected over fiberglass insulation, especially when there are cold and warm climate conditions to be tackled.

3. Rigid Foam Board Insulation

Though we offer listed prices for this type of insulation, one of its benefits is its high insulation value per inch. In layman’s terms, this means you are getting a high R-value or protection from heat or cold. Rigid foam insulation can be applied to the exterior and interior of the structure. It is made from polystyrene, polyisocyanurate, or polyurethane.

- Positive Features: Since it has a high R-value per inch, it requires minimal thermal bridging. In addition, it will add structural integrity to the structure. You can apply it against the interior metal members or beneath exterior cladding,

- Negative Features: It will cost you more than most available options. For this reason, as well as the fact that it requires protective barriers for fire safety and must be cut to fit corners,Factory Steel Overstock has refrained from offering it on our site.

4. Spray Foam Insulation

One can’ t argue that spray foam insulation is also a popular barn insulation type. After all, it can seal gaps and crevices because it expands once applied. Closed-cell spray foam has a higher R-value and moisture barrier than open-cell. However, due to its expensive cost, Factory Steel Overstock has elected not to offer this insulation type. Review our metal building insulation prices and choose what you feel is best for you.

- Positive Features: Since it fills gaps and difficult-to-reach areas, it’s a good air and moisture barrier. In addition, it adds structural integrity and a high R-value per inch (the closed-cell version).

- Negative Features: This is not insulation that the average layperson can’t install. Consequently, a professional installer is required. This adds to the cost. It cost more than our fiberglass insulation price. For this reason, you will not see this insulation amount Factory Steel Overstock’s metal building insulation prices.

Metal Building Insulation Rolls

You should make sure, no matter what metal building insulation rolls you choose, they are installed correctly. The 4 points below are also important:

- Get the R-value that is needed: The R-value measures the protection the structure gets from heat and cold. Select the appropriate R-value for the applicable climate.

- Starting the project the right way: Make sure the area where you will install the insulation is clean so that everything fits well. If the surface you are applying your insulation is not cleaned correctly, it will affect the R-Value

- Secure the rolls: Your insulation should be tightly attached, leaving no gaps. If you notice any gaps, seal them.

- Periodically assess the installed insulation: All insulation is affected by time, so periodically confirm the insulation status.

Metal Building Insulation Rolls are precisely cut for the standard member spacings of metal structures. They are usually made of fiberglass or mineral wool and designed to be laid over the purlins or fitted between the steel members before the exterior sheeting is applied.

- Positive Features: It is considered the most cost-effective insulation. It is easy to install by a layperson and often done without professional assistance. Like all insulation, it improves thermal performance and reduces condensation. No matter how large the size structure is, it is easily installed.

- Negative Features: It has lower R-values than rigid and spray foam and can sag over time if not correctly installed. However, because of the cost-effectiveness and ease of installation, Factory Steel Overstock believes it is a better value overall than rigid or spray foam.

Pole Barn Insulation Rolls

These rolls are identical to metal building insulation rolls but are designed for the spacings of wooden pole barn structures. Like metal building insulation rolls, they are used for energy efficiency, to prevent condensation, and to control airflow.

- Positive Features: It is easy to handle and install, designed to fit the typical spacing of pole barn framing, and effective at reducing heat transfer.

- Negative Features: It can be bulky and has a lower R-value per inch than foam options. Again, because of its cost-effectiveness and ease of installation, Factory Steel Overstock recommends it.

Getting the correct metal building insulation rolls is key to keeping your structure cool in the summer and warm in the winter. Knowing about the different kinds of insulation types, their benefits, and how to install them correctly will save you money in the long run.

How to Choose the Correct Metal Building Insulation type

Ultimately, there are many factors you should consider when selecting an insulation type for your metal building or pole barn—for instance, climate, the building’s use, budget, and energy efficiency goals. High R-value insulation types are preferable in colder climates, while in warmer or humid areas, one should consider reflective insulation types. When the highest- performance is required, consider rigid or spray foam; however, keep in mind that the cost will increase. The more cost-effective insulation, like fiberglass or reflective, combined is often the choice for larger projects or areas with milder climates. Some have even chosen to combine insulation types such as fiberglass and reflective to optimize performance.

Comparison of Vinyl-faced insulation and Vinyl-backed insulation

The terms vinyl-faced insulation and vinyl-backed insulation are often used interchangeably, but they can have slightly different meanings. Here’s a breakdown of the potential differences:

Vinyl-faced insulation consists of fiberglass or mineral wool with a vinyl sheet on one side. This type of insulation serves as a vapor barrier to protect against moisture and condensation damage. Conversely, Vinyl-backed insulation, also made of fiberglass or mineral wool, has a vinyl layer on the opposite side. Though it provides protection, it isn’t a primary vapor barrier.

Key Difference

- Vinyl “Backed” implies support, usually not exposure. This type of insulation is less common than faced. It is utilized where the facings help hold the insulation in place and reinforce the insulation.

- “Faced” usually refers to the visible or finished side, intended to be seen. Traditionally, this type of insulation was purchased for pole barns and metal buildings.

Choosing Between Batt and Blanket Metal Building Insulation

Let’s dive into the difference between batt and blanket metal building insulation:

Simply stated, when people are referring to batt insulation, they mean the insulation is precut. In turn, when referring to blanket, the insulation has not been cut.

Batt insulation, often made of fiberglass, is a prevalent insulation type found in homes. It is an excellent DIY insulation type because it is easy to install and cost-effective. Although it comes in pre-cut panels, you still have to be careful fitting around obstacles like pipes and wiring. If you aren’t patient and focused, you can easily leave gaps, causing a loss of energy efficiency.

Blanket Insulation, conversely, usually arrives in large, continuous rolls that can be cut and trimmed to fit whatever space demands. It is often the choice for large, open areas with few obstacles. It’s also cost-effective and easy to install, like batt insulation. Like with batt, you should wear protective gear when installing to avoid skin irritation or inhalation of fiberglass particles.

When selecting between the two insulation types, consider the nature of your project. If the area to be insulated has obstructions, pre-cut batt insulation is the wiser choice. But if you’re looking to insulate large, unobstructed areas, blanket insulation provides the better choice. Regardless of your choice, both options are energy efficient and commonly used for DIY metal building projects.

Four Insulation Rolls

Below are four insulation rolls to review. Click the “Buy Now- Fill Out Order Form” button on the preferred insulation rolls. Then, fill out an order form (specifying the offered profit amount). Questions, call 1-888-512-1116.

VR-R (Plus)

Normal Strength insulation rolls

Pros: Reinforcement: tri‑directional fiberglass scrim

Its metallized polyester backing allows the insulation rolls to reflect radiant heat away from the structure.

The fiberglass scrim reinforcement, combined with the metallized polyester backing, makes the facing tougher than simple film/kraft versions, better resisting tearing, puncturing, and splitting at seams. “Plus” version generally refers to a heavier or better lamination/reinforcement. The thinner vinyl layer means it is easier to roll, cut, and install.

It is our most popular economical option.

Cons:

While stronger than basic facings, it cannot match the durability of WMP-30 or WMP-50 facings.

WMP-10

Superior Strength insulation rolls

Pros: WMP-10 insulation rolls feature a 0.2 perm rating (very low) per ASTM E96. This means it is an excellent vapor retarder and remains stable across a wide range of temperatures.

The white film kraft backing has a relatively clean, attractive look with good light reflectance (85%).

ASTM E84 / UL 723: Flame Spread/The fire rating is Class A-1.

Cons:

Manufacturers label it as not as heavy-duty as other facings. For high-abuse applications (such as heavy machinery, forklifts, rough handling, frequent contact, or impact), they suggest a stronger facings e.g., WMP-30, WMP-50, or facings with metallized polyester backs like VR-R -plus).

WMP-30

Industrial Strength insulation rolls

Pros: With its 0.02 perms (very low), the insulation rolls have an an excellent vapor retarder. This means the facings reduce moisture diffusion through wall and roof assemblies. This results in a reduced condensation risk.

WMP has stronger and heavier facings than WMP-10. Therefore, it is more resistant to puncture, tearing, and general abuse.

Cons:

WMP-30 insulation rolls have a thicker facing; therefore, the rolls are stiffer and less flexible. This means it will be more challenging to manage in tight spaces, around curves, or when used by a single person.

Select WMP-30 if you want the same low per-rating as WMP-10, yet require tougher and more durable facings.

WMP-50

Premium Strength insulation rolls

WMP‑50 is the heavyweight champion of the four insulation roll facings. It has the most robust, durable, and strongest facing.

Like WMP-VR (plus), its metallized polyester backing allows it to reflect radiant heat away from the structure.

It also has a low Perm Rating 0.2; therefore it also is an excellent vapor retrded.

The WMP-50 Tensile Strength (MD / XD 65 lb/in / 60 lb/in)

The fire rating is Class A-1.

It’s designed for premium heavy‑duty use

Cons:

WMP-50 insulation rolls are stiffer and less flexible, since the insulation is thicker. This means it will be more challenging to manage in tight spaces, around curves.

Metal Building Insulation Accessories

List your desired metal building accessories on the order form.

Two-Sided

$35

Double-Sided Tape

Typically used before the sheeting is installed, double-sided tape provides a temporary hold for insulation. It helps keep the insulation in place during installation until the final sheeting is applied.

3″ x 150′. Recommended one roll per 2,000 square feet.

Patch Tape

$35

While the insulation facings are designed for high durability against punctures and tears, patch tape is essential for sealing small rips, gaps, seams, and joints. It helps maintain a continuous thermal envelope and ensures long-term performance.

1/2″ x 60′. Recommended one roll per 15,000

Banding

$195

Banding (Wire)

Commonly used in retrofit installations with faced insulation, banding prevents the insulation from sagging or shifting over time. It adds support, especially in overhead or vertical applications.

One roll of 500′ banding per 1,000 square foot of coverage.

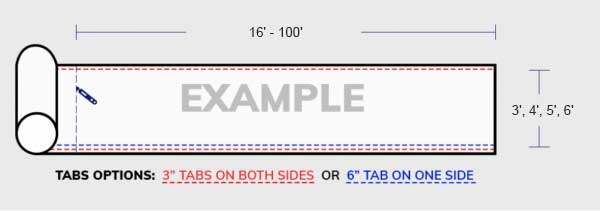

List the roll dimension you desire on the order form

Standard roll dimensions are 30′ – 100′; rolls less than 30′ incur an additional $0.05 per square foot.

Barn Insulation

A protective fiberglass facing metal barn insulation will deliver year-round benefits, whether you are located in the North, South, East, or West. Proper insulation helps maintain consistent indoor temperatures while reducing energy costs. Since metal sheeting sweats, the right barn insulation reduces condensation, shielding equipment and animals from moisture-related damage. One of the added benefits of barn insulation is that it also enhances sound control and comfort. What’s the benefit of having a structure if you’re reluctant to go inside due to temperature or noise discomfort? Ultimately, your metal barn insulation prolongs the lifespan of your building by mitigating corrosion and thermal stress, thereby safeguarding it against damage.

Within this page, you are given the liberty to access the actual cost before profit has been added. Then you are given the bonus privilege of suggesting a profit amount you believe is fair and acceptable. This alone separates Factory Steel Overstock from other sources.