Scroll down to the WMP-10 Fiberglass Facing order form. It is below the Fiberglass Insulation Wholesale Calculator. Then fill out the form.

WMP-10 Fiberglass Facing

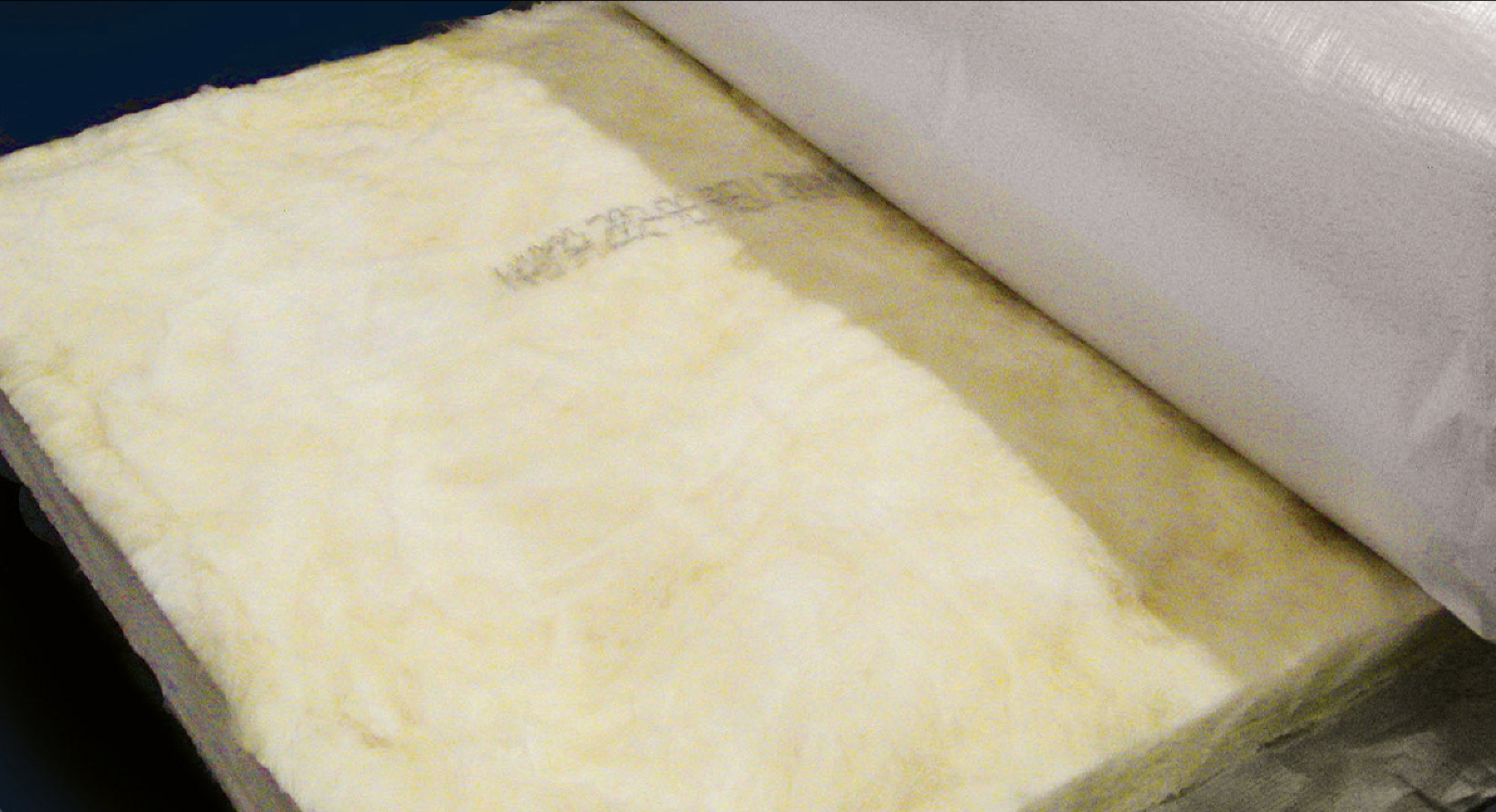

Our clients like our WMP-Fiberglass facing because it performs well and holds up over time. It was designed specifically for metal buildings, and its best quality is that it controls moisture, with a vapor retardant rating of about 0.09—ideal for reducing condensation and protecting your interior building space, Though it doesn’t have a perm rating of WMP-VR-R Plus, it is more than adequate for building not located in high humidity areas. Often selected over WMP-VR-R because of the lower price; however, WMP-VR-R (plus) is currently on sale, therefore, maybe the better purchase right now.

The WMP-10 offers tensile strength of approximately 85 pounds per inch and puncture resistance between 25–35 pounds per inch; therefore, more than adequate for the rigors of installation and everyday wear. The polypropylene scrim reinforcement adds durability while keeping a clean, white finish that brightens up interiors.

Class A fire-rated and also has a bright white facing that reflects light well, which helps to cut down on lighting needs and enhance energy efficiency.

Additional information on WMP-50 fiberglass facing is listed with tabs located below the Quote form.

Tape and Banding for WMP-10 Fiberglass Facing

To maintain the insulation’s thermal efficiency, order patch and/or double-side tape and/or banding and screw (white or black).

Two-Sided

$35

The purpose of the WMP-10 Fiberglass Facing DOUBLE-SIDED tape is to secure insulation during the construction process.

3″ x 150′. Recommended one roll per 2,000 square feet.

Patch Tape

$35

The WMP-10 Fiberglass Facing PATCH TAPE is used to seal gaps, joints, and seams, ensuring a continuous thermal barrier.

1/2″ x 60′. Recommended one roll per 15,000

Banding

$195

Banding is used to prevent the WMP-10 Fiberglass Facing from sagging and shifting.

One roll of 500′ banding per 1,000 square foot of coverage.

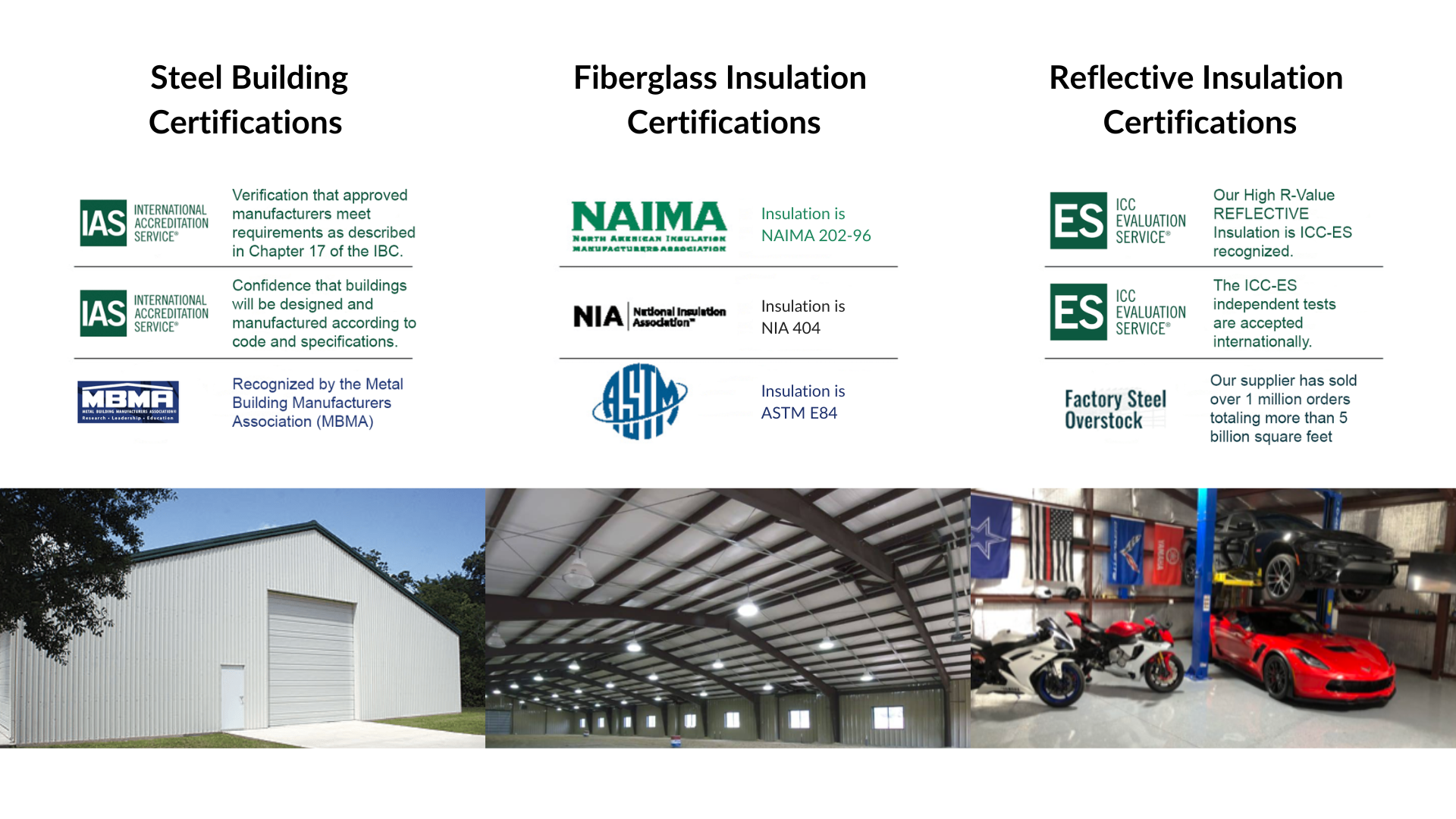

Our Low-Cost WMP-10 Fiberglass Facing reflect these specifications and certifications.

Why pay more for the exact specifications, certifications (NAIMA,NIA, and ASTM) and materials?

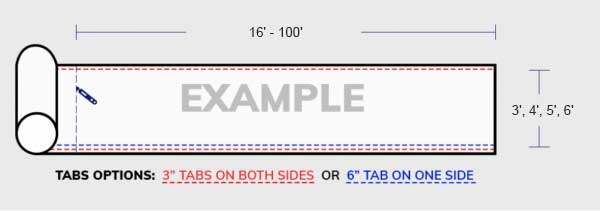

Reinforced fiberglass Roll dimensions

Standard Length: 16′ – 100′.

Standard Width: 3′, 4′, 5′, and 6′

Custom cuts shorter than 16′ are an additional cost.

WMP-10 Fiberglass Facing – Order to Delivery

1. Order Insulation Rolls

After calculating savings, click “Buy Now” and complete the Order Form. To begin your order, pay the brokerage fee to Factory Steel Overstock

2. Confirmation Email

You’ll receive a confirmation email within one business day, including your Order Number, supplier contact details, and easy-to-follow instructions to complete your payment to supplier.

3. Scheduled Delivery

Our shipping team will contact you to schedule a convenient delivery date. Expedited shipping arrives in 7–10 days, and standard delivery takes 11–21 days.

4. Sign for Delivered Rolls

When your insulation rolls arrive, simply take a moment to inventory the items, then sign to confirm delivery—ensuring everything is in order for a smooth installation process.

Selling the Right Way