Buy WMP-50 Fiberglass Facing by filling out the order form below. Located below the Fiberglass Insulation Wholesale Calculator

Features and Benefits of WMP-50 Fiberglass Insulation

The WMP-50 fiberglass facing is our strongest facing against punctures and tears! It is simply the heaviest-duty option available to protect your fiberglass insulation – period! It, too, was designed for metal buildings; however, it was made for situations where moisture, wear, and rugged conditions are a daily reality! Ideal choice for purposes like large commercial riding arenas, industry machinery structures, and gymnasiums with heavy traffic.

Here are the specifications: WMP-50 Fiberglass Insulation. Its vapor rating is approximately 0.02, making it an ideal choice for addressing moisture concerns. The WMP-50 has a minimum tensile strength of65 lbs. per inch. The Mullen Burst PSI is 120 lbs. It features a heavy-duty tri-directional fiberglass scrim with a durable white polypropylene exterior, providing it with serious tear resistance and long-term performance.

Additionally, the WMP-50 is Class A fire-rated, featuring bright white, attractive facings that help reflect light, thereby reducing energy costs.

The wholesale price adds a huge advantage: you can purchase the WMP-50 at a cost equal to or better than most firms charge for the WMP-VR-R plus.

Please note that because the WMP-50 facing is thicker, it can be slightly more challenging to install than the lighter facings.

Refer to the product’s technical data sheet for the most accurate and detailed specifications of the WMP-50 Fiberglass Facing (see the Specification tab located below the order form).

Tape and Banding for WMP-50 Fiberglass Facing Insulation

To maintain the insulation’s thermal efficiency, order patch and/or double-side tape and/or banding and screw (white or black).

Two-Sided

$35

The purpose of the double-sided tape is to secure WMP-50 fiberglass facing during the construction process.

3″ x 150′. Recommended one roll per 2,000 square feet.

Patch Tape

$35

This tape is used to seal gaps, joints, and seams, ensuring a continuous thermal barrier for WMP-50 fiberglass facing.

1/2″ x 60′. Recommended one roll per 15,000

Banding

$195

Banding is used to prevent the WMP-50 fiberglass facing insulation from sagging and shifting.

One roll of 500′ banding per 1,000 square foot of coverage.

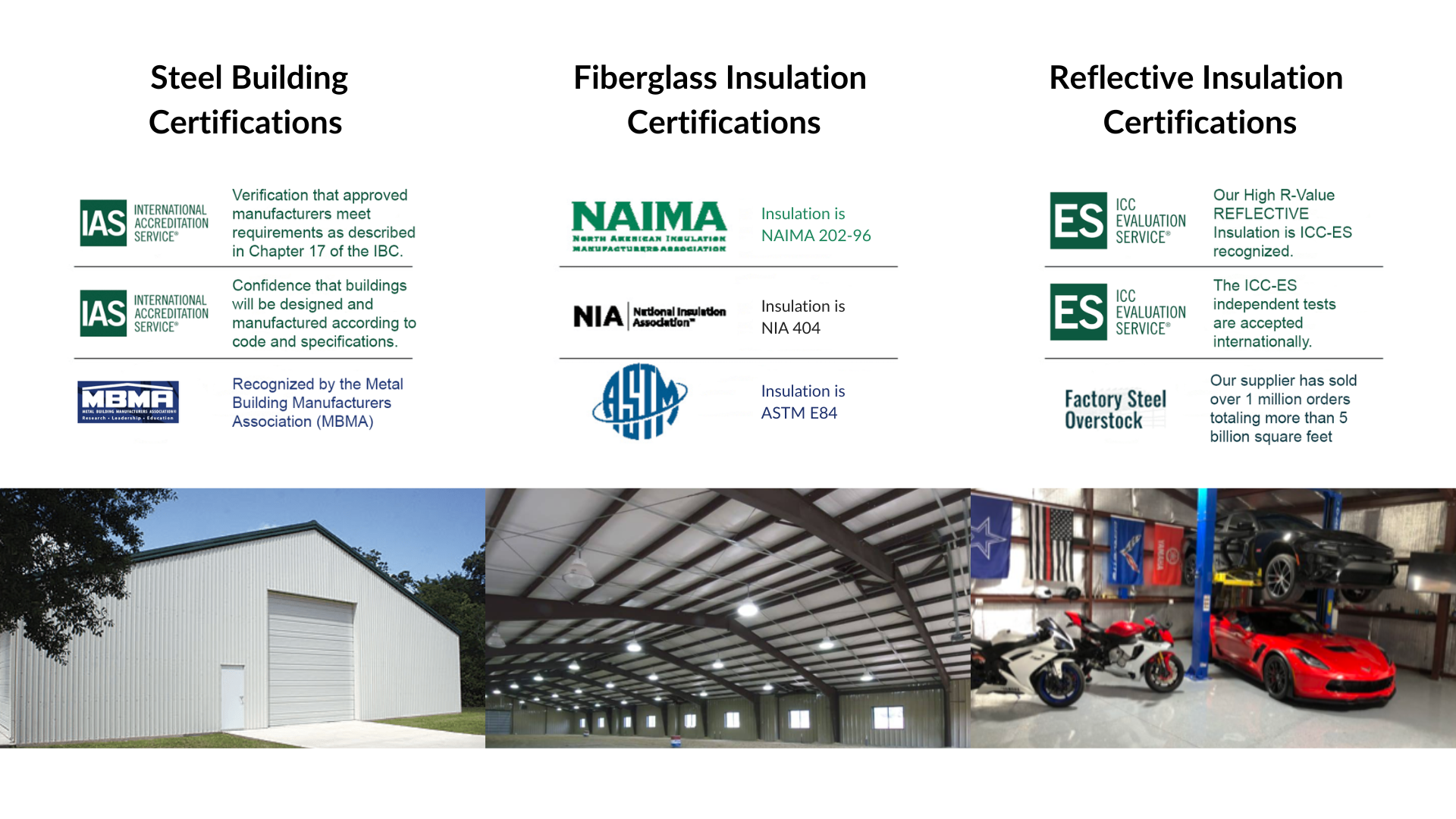

Our Low-Cost Fiberglass Insulation Prices reflect these certifications.

Why pay more for the exact specifications, certifications, and materials originating at the same plants?

For more information, click Fiberglass Resource Guide

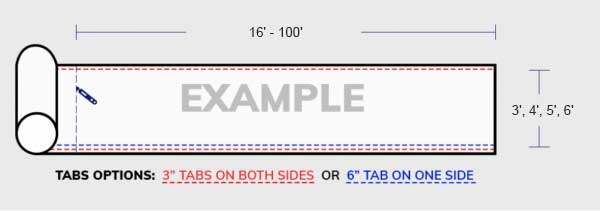

Reinforced fiberglass Roll dimensions

Standard Length: 16′ – 100′.

Standard Width: 3′, 4′, 5′, and 6′

Custom cuts shorter than 16′ are an additional cost.

WMP-50 Fiberglass Facing – Order to Delivery Process

1. Order Insulation Rolls

After calculating a WMP-50 Fiberglass Facing savings, click “Buy Now” and complete the Order Form. You will list on the form a fair profit amount you are willing to pay today.

Our agent will evaluate your order and indicate whether it has been accepted when you call. If approved, please have the integrity to pay that same day.

2. Confirmation Email

You’ll receive a confirmation email within one business day, including your Order Number, supplier contact details, and easy-to-follow instructions to complete your payment to supplier.

3. Scheduled Delivery

Our shipping team will contact you to schedule a convenient delivery date. Expedited shipping arrives in 7–10 days, and standard delivery takes 11–21 days.

4. Sign for Delivered Rolls

When your insulation rolls arrive, simply take a moment to inventory the items, then sign to confirm delivery—ensuring everything is in order for a smooth installation process.

Selling the WMP- 50 Fiberglass Facing The Fair Way

No dealing with commission salespeople using questionable sales gimmicks. You calculate the wholesale price yourself to confirm savings for FREE. Then, you offer a profit amount that aligns with your expectations.