Specifications

Our standard specifications are other companies’ options.

The Highest Quality Metal Building Details

Metal Building Framing Details are International Accreditation Service (IAS) accredited

A steel building system consists of many significant members. If a few or possibly even one member is missing, miscut, or designed incorrectly, delays and added construction costs could occur. Therefore, it is wise choice to buy from an IAS accredited manufacturer.

Based on design criteria, our IAS-certified manufacturer fabricates metal building detail structural members…

| Hot-Rolled | Cold-Formed | Built-Up | |

| Mainframes | X | — | X |

| Interior columns | X | — | X |

| Wind columns | — | — | X |

| Portal frames | X | — | — |

| Roof wind struts | X | — | — |

| Endwall frames | X | X | — |

| Jambs & headers | X | X | — |

| Purlins & girts | — | X | — |

| Eave struts | — | X | — |

| Misc. angles & braces | — | X | — |

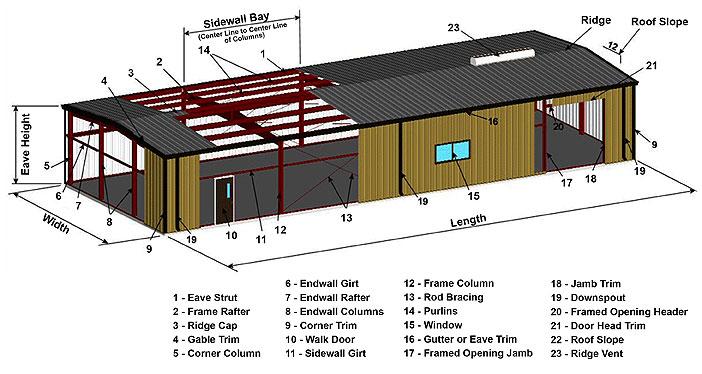

Solid-Beam Metal Building Structure

The key feature of a rigid frame metal building structure is the I-beam mainframes. The material used is 50,000 p.s.i. yield strength (Some manufacturers use only 34,000 p.s.i. yield strength material). Frames are single bead, continuous submerged arc welded by automatic welding machines to help ensure quality. Factory-applied rust-inhibiting primer is used to help protect the mainframes and secondary material during the erection process.

End Wall Frames and Columns

are either cold-formed, hot-rolled, or built-up “I” sections depending on design requirements. On most structures, only a PB (Posted Beam) end wall is required. This means the frames only need to support half the load of a mainframe. At times it is advisable to use a Non – Expandable. A non -expandable end wall is larger than a (PB) and was implemented when X bracings weren’t able to use in the end wall. Lastly, there is an Expandable Endwall. This is a full I-beam and is usually utilized when a customer wants to extend the building length in the future.

Metal Building Secondary Framing Detail

Wall girts, roof purlins, and eave struts are considered secondary members. These members do not carry much of the overall loads; however, they support the walls and roof panels. In addition to this, they transfer loads to the frames and help stabilize the building.

GIRTS SPECIFICATIONS (in the sidewall) and PURLINS (in the roof) are a minimum of 8” to 10” to meet design requirements. Cold rolled Z-section, 12 to 16 ga, 57,000 p.s.i. yield material is used to provide maximum strength.

The bypass girt system overlaps at sidewall columns forming a continuous “span” for extra strength. All girt clips are factory welded for easier erection.

PURLINS are top-mounted on the rafter with a varied lap of 1’6” to 5’ for strength and cost savings in erection labor. Maximum purlin spacing is 5’ on center. (picture)

EAVE STRUT is a cold-formed C-section that is rolled for the appropriate roof pitch to help insure weather tightness at the eave. (picture)

RAKE ANGLE is supplied for the attachment of the sheeting at the rake of the building for ease of installation.

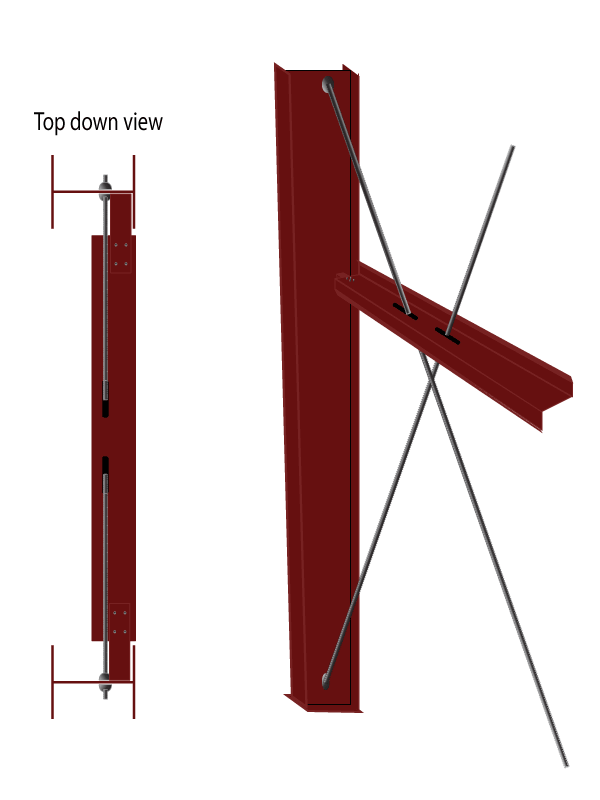

Bracing

In order for a building to handle the stresses such as torsion, lift, compression and shear, it must have some form of bracing. The primary bracing utilized by steel buildings are X BRACING, FLANGE BRACING, DIAPHRAM BRACING, WIND COLULMS, and PORTAL FRAME.

X bracing uses steel rods or cables that extend diagonally from frame to frame. They keep the building tightly connected. All diagonal galvanized cable bracing is supplied for the roof and walls to remove longitudinal load from the structure. All cables are pre-stressed and pre-made for easier erection.

Diaphragm bracing stems from wall and roof sheeting. The sheeting acts like a “securing force” keeping everything together.

Angle Flange Bracing is provided for the connection of the rigid frame to the purlins and girts. This ensures the allowable compressions are adequate for any combination of loading.

To reinforce a column, a wind column is used.

A portal frame is columns placed within a bay (vertically and horizontally) in lieu of X bracing.

Canopies and Roof Extentions

Canopies– are optional on the sidewalls

Purlin Extensions– are optional on the end walls

These are the most common items added to orders, simply because they enhance the building’s appearance and performance. The additional cost is minimal -with purlin extensions less costing than canopies. Our extensions are 1’ to 5’ and a soffit is a standard feature.

Metal Building Sheeting Details

DEEPER HIGH-RIB SHEETING 26 gauge (1 ¼” PBR), 80,000 P.S.I. yield strength material with more frequent corrugations that provides extra strength than an R profile as well as has a larger overlap. Some firms use an R panel for their roof sheets (picture on right). Most pole barns and tube buildings use a lighter 29-gauge sheeting thickness. Some manufacturers use a lower yield strength material, which is less resistant to damage from hail or other impacts.

Rib Spacing: 12” on center. Coverage 36”.

Quality Product Details Numerous UL 580 ratings are available, as well as UL 790, Class A for external fire, roof assembly for UL 263 for internal fire, and the UL 2218 Class 4 impact rating. PBR carries Florida approval, Dade County ratings, and FM 4471 approval standard for Class 1 panel roofs.

Liner panels (optional)

(29 or 26 gauge) are a standard 3’ wide panel that screws into the framing. They run the entire building or to the eave height or to the standard 7’4” girt. A connection point at the base is required when you order liner panels. Your liner panel will enhance your building’s appearance as well as protect the interior wall and any insulation.

Trim

Many times, the first thing one notices is the trim because its purpose is to highlight a building. Needless to say, poor-looking trim makes the building look cheap and ragged, wherein nice sculptured trim will make your building look finished and professional. Your trim accomplishes two things: It connects the transition areas which helps seal the building and protect it from moisture. Unfortunately, many companies save money by simply supplying generic trim that has to be field located to fit. This compromises the integrity of the building as well as they look. Factory Steel Overstock offers a sculptured trim specifically designed to fit your structure. The snug fit makes the erection process easy and you experience many years of durability.

Gutters & Downs (optional)

Some consider the gutters and downs an accessory; however, they perform some of the same functions as the trim. Not only do they enhance your building’s appearance, they also control the rain runoff. Factory Steel Overstock offers a standard gutter & downs for low snow areas and a stronger design for heavier snow areas. In areas of high snow, we don’t recommend gutters and downs.

Color & Galvalume Plus Finish Warranty

40-year warranty on premium color finish on walls and trim. The roof finish is Galvalume Plus or premium colored finish. Galvalume Plus roof warranty is 30 years.

ALL COIL STEEL has a minimum Galvalume substrate to help prevent deterioration of the steel sheeting.

FRAMED OPENINGS

Have cold-formed C-section jambs and headers to help ensure easy installation of overhead doors, etc. Framed openings large enough for a car to drive in, require anchors to the concrete. In order to increase profits, many sellers offer only “field located” framed openings. However, this action means the customer must carefully cut into the steel members at the job site without directions. Other than walk door or window openings, we suggest the manufacturer always design and frame the openings. With Factory Steel Overstock, the general public will always receive these large “factory-located” framed openings that are FULLY FLASHED! This means the attractive openings will be shown in the certified plans as well as the parts will be precisely pre-cut and labeled. The significance of this is each metal building system is designed to withstand the demands and stresses of the different openings put on the design.

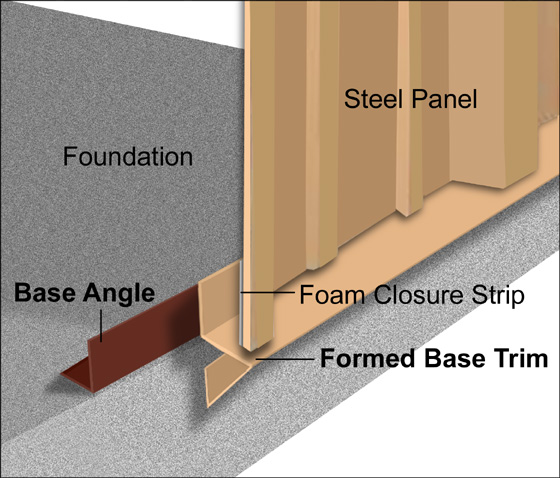

Base Conditions

Your base condition determines provides a lower connection for your wall panels as well as how the panels relate to the wall panels. Below are the common 4 base conditions:

Standard base angle – The base angle is to be attached to the concrete with ram-sets or equivalent anchors. However, this base condition requires that the slap be formed with a 1” sheeting notch. This notch increases the concrete cost; therefore, we believe a better investment is to simply order a different based option.

Formed base trim – If you want to finish off your building nicely, simply request Formed base trim. This attractive item also seals the bottom of the building more effectively than the foam closures. Unwanted creators may penetrate through the foam, but they won’t be able to get through our sturdy formed base trim!

Base girt – When you don’t have a slab or perimeter foundation because your building is sitting on piers, base girts 3” to 6” above the floor are utilized. It attaches to clips on the column.

Base channel – When liner panels or an interior wall are going to be used, one selects a base channel. A “cee” section is used as a connection point for inside panels. It sits flush with the foundation.

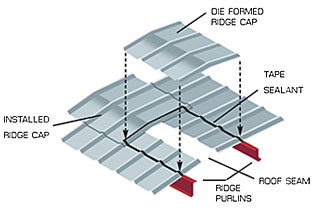

CLOSURES

CLOSED CELL NEOPRENE STRIPS are used to help seal building. Located at eave, gable, and at the base of building to help provide weather tightness. Pre-formed shapes to match panel configuration providing a tighter seal.

SEALANT for roof side laps, end laps, and flashing at gable is provided to help insure weather tightness. Thick pressure-sensitive tape sealant for ease of installation.

SELF-DRILLING AND SELF-TAPPING FASTENERS are pre-assembled with neoprene washers and metal caps to help insure weather tightness. Since a roof is more exposed to the elements than other walls, extra precautions should be taken for its protection. The most common cause of rust for any steel building is the screws. Though the vast majority of steel roof panels are covered with a galvalume coating or paint, the fasteners penetrate this painted surface; therefore, causing steel–to–steel contact. Therefore, Factory Steel Overstock only offers the highest quality long-lasting fasteners that do not rust! Their unique design washers protect the connection from moisture.

RIDGE CAP

LONG OVERLAP to help prevent water from siphoning into buildings. Factory Steel Overstock offers die-cast ridge caps that connect the roof panels. The ridge cap covers the peak. Some sellers offer ridge rolls that are bent in the field and sealed with closures. Moreover, fitting them is difficult and over time they may deteriorate enables birds to nest in that area. Rest assured, our ridge caps match the panel profile and the roof profile; therefore, leaving no area leaks or pests.

Metal Building Plans and Framing Details

Free (Initial) Certified Building Plans for ALL 50 states.

- Letter of Certification

- 2 sets of certified stamped erection plans provide step by step instructions for assembly.

- 2 sets of certified stamped anchor bolt plans that includes reactions for foundation design.

ENGINEER CERTIFIED APPROVAL DRAWINGS upon request: Includes wall and roof framing diagrams, cross-sections, sheeting, and flashing details are provided. These drawings clearly show the proper erection and assembly of all building components.

ALL PARTS ARE NUMBERED A part number is placed on each component (not including sheeting, screws, etc.). These part numbers coincide with a detailed listing contained in the bill of materials that come with your building. The same numbers are also used on the drawings for clarity and to help with assembly on the job site.

Foundation Plans Resource

While the typical certified foundation design costs $2,500 to $3,000, Factory Steel Overstock provides a resource for some states – you only pay $1,200, $400 of which will be paid to FSO, and $800 to the foundation engineer.

Available states: WA, OR, CA, ID, NV, AZ, WY, UT, and CO. Request at time of building order.

KEY FEATURES included with EVERY purchase:

- 40 Yr. Warranty on Colored Walls and Trim

- Solid I-Beam Construction

- Clear span design (no interior columns)

- Lifetime Structural Warranty

- Complete Sculptured Trim Package

- Framed Openings Fully Flashed

- 30 Yr. Warranty Galvalume Plus Roof Finish or 40 Yr. Warranty on Colored Roof

- 26 Gauge sheeting -80,000 p.s.i. tensile strength

- 1 1/4″ sheeting profile

- Purlin bearing rib (PBR panels – larger overlap than R panels). All panels incorporate the purlin bearing profile.

- Long-life roof fasteners that match selected building colors.

- All bolts, screws, closures, weather stripping, sealants, fasteners as required to erect structure

- The pre-punched connecting clips for the structural members, including endwall columns, are welded in place and then primed during fabrication

- All structural elements for the specified framed openings (jamb, girts and headers) are pre-cut and pre-punched and the necessary clips are welded on during fabrication

- Anchor bolts and erection services by other. Manufacturer has IAS accreditation as well as MBMA (Metal Building Manufacturer Association) membership.

Cost-Plus Program Made Simple

A 35-year industry veteran presents a spiritual approach by allowing those prepared to give back TODAY a wholesale quote without an upfront cost.

- Review 1 to 3 market quotes as well as our posted insulation prices and steel building prices.

- Fill out one of these forms: Name Your Price, Wholesale Metal Building Quote, and Wholesale Insulation Quote.

- Call 1-888-512-1116 to let a representative know you submitted a form and to go over the details submitted.

- After the quoted savings, pay the low service fee that SAME DAY: $350-$500 Insulation orders – $750-$1,500 Steel Building orders.

- For a full process, click – Order To Delivery

- Reflective insulation is delivered in 7-10 days. Receive Order #. Ships the next day! Receive a call from the shipper before delivery.

- Fiberglass insulation is delivered in 2-3 weeks. Receive Order #. Receive a call from the shipper before delivery.

- Steel Building Kits are delivered in 8-10 weeks. Receive the Order # and Scheduling information. Certified plans completed within 4 weeks. Receive a call from the shipper before delivery.

With Factory Steel Overstock, you take control from the start by Naming Your Price

Smart buyers utilize a transparent Wholesale Cost-plus programs over traditional retail outlets.

We promise to return all calls, emails, and text sent during a work week within 24 hours.

We are so confident in our efforts, that we are willing to give you back our fee if you don’t receive the services noted

You are guaranteed a net savings below market quotes of equal specifications.

Helpful Links